In tin ore processing, jig separation is recognized not as a simple legacy technique, but as a highly efficient gravity-based pre-concentration method with strong industrial relevance. Owing to its robustness, low operating cost, and adaptability to variable feed conditions, the jig separator is widely applied in both alluvial tin deposits and suitably liberated hard-rock tin ores.

1. Tin Ore Characteristics and Implications for Process Design

Cassiterite exhibits a density of approximately 6.8–7.1 g/cm³, while common gangue minerals such as quartz and feldspar typically have densities of 2.6–2.8 g/cm³. This significant density contrast makes tin ore particularly suitable for gravity separation as a primary beneficiation method.

From an engineering perspective, tin ores encountered in practice can be broadly classified as:

- Alluvial (placer) tin ores, where cassiterite occurs as liberated grains with minimal intergrowth, favoring direct washing, sizing, and jigging.

- Hard-rock tin ores, in which cassiterite is disseminated in quartz veins or granitic matrices, requiring controlled crushing and, in some cases, grinding to achieve adequate liberation.

- Polymetallic tin ores, commonly associated with tungsten, tantalum–niobium, or iron minerals, where jigging serves as a first-stage concentrator prior to more selective gravity or magnetic separation.

A clear understanding of ore characteristics directly determines the required degree of comminution and the optimal positioning of the jig within the flowsheet.

2. Operating Principle of Tin Ore Jig Separation

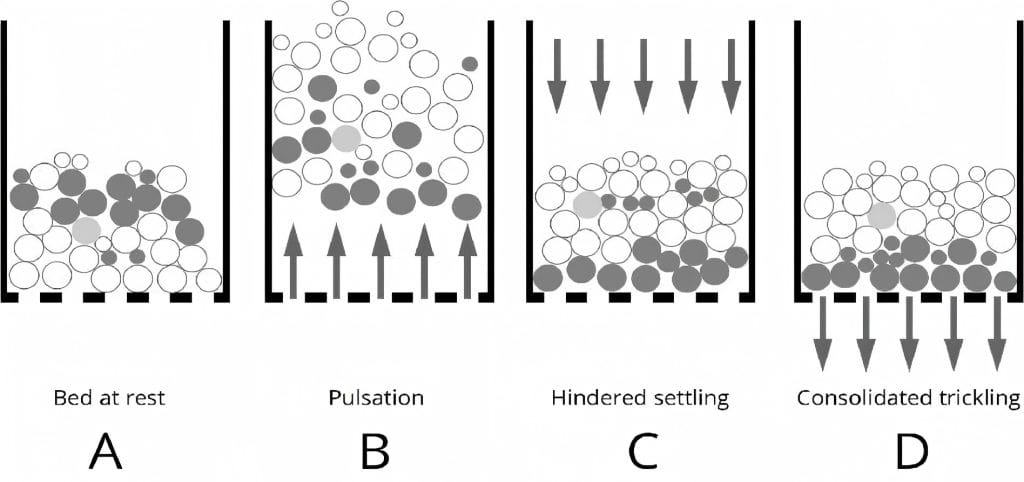

A jig separator operates by subjecting a particle bed to periodic vertical pulsation of water, inducing alternating expansion and compaction of the bed. During this dynamic process, particles stratify primarily according to density and, to a lesser extent, size and shape:

- High-density cassiterite particles migrate rapidly toward the lower strata of the bed and are recovered as concentrate.

- Low-density gangue minerals remain in the upper layers and are discharged as tailings.

- Intermediate particles are controlled through adjustment of operational parameters such as stroke length, pulsation frequency, and water addition.

Jig separation maintains stable performance over coarse and intermediate particle sizes, typically 0–10 mm, with low sensitivity to short-term feed fluctuations.

3. Typical Jig-Based Tin Ore Processing Flowsheet

In a technically optimized tin ore processing plant, jigging is positioned after adequate liberation and size classification. A representative flowsheet includes:

Washing and Desliming

Clay and fine slimes are removed to prevent surface coating of cassiterite particles, which would otherwise reduce gravity separation efficiency.

Screening

Feed material is separated into narrow size fractions (e.g., 0–2 mm and 2–10 mm) to ensure consistent bed behavior and stable jig performance.

Jigging for Pre-Concentration

The tin ore jig performs bulk upgrading by rejecting a significant proportion of low-density waste at an early stage.

Cleaning

Jig concentrates are treated by shaking table cleaning or combined with magnetic separation to meet final product specifications.

This staged approach reflects best practice in gravity-based tin beneficiation, balancing recovery, grade, and operating cost.

4. Technical Advantages of Jig Separation

From an operational and economic standpoint, jig separators offer several decisive advantages:

- High unit capacity, enabling continuous treatment of large tonnages.

- Good tolerance to feed variability, particularly important in alluvial tin deposits.

- Low energy consumption and simple maintenance due to a mature mechanical design.

- Effective pre-concentration capability, reducing the load and cost of downstream fine separation equipment.

These advantages make jigging particularly suitable for projects requiring cost control and long-term operational stability.

5. Case: African alluvial tin ore processing

An African alluvial tin project processes placer material containing minor clay. Cassiterite particle size is predominantly 0–10 mm, with good natural liberation but relatively low head grade.

- Washing & Screening: A rotary scrubber equipped with a trommel is used for clay removal and screening into 0–2 mm and 2–10 mm fractions.

- Jigging:: 2–10 mm fraction treated by an LTC jig for roughing, 0–2 mm fraction treated by a fine-particle JT jig

- Cleaning: Shaking table cleaning for final upgrading

Through a combined jigging and shaking table process, a large proportion of waste is rejected at the early stage, and a tin concentrate grade of approximately 70% is achieved with stable overall performance.

Conclusion

In practical tin ore processing, the jig separator should be regarded as a key pre-concentration unit rather than a final recovery device. With proper size classification, jigging significantly improves process economics by upgrading ore early and reducing downstream investment and operating pressure.

For alluvial tin ore and non-ultrafine hard-rock tin ore, jig separation remains one of the most proven and reliable gravity separation technologies in industrial application.

For further information on tin ore processing, or project feasibility evaluation, please contact us directly via WhatsApp: