Product

Gold ore is mainly divided into rock gold ore and alluvial gold ore, their physical and chemical properties are different, so the beneficiation methods are also different.

Rock gold ore is relatively dense, while the vein associated with rock gold ore is relatively less dense, and there is a certain specific gravity difference between them, so the gravity beneficiation method can be used to recover rock gold ore. Rock gold ore also needs to go through crushing process or even grinding process before beneficiation.

Alluvial gold ore beneficiation method is similar to alluvial tin ore, gold is free in alluvial gold ore, mostly in the form of flakes or granules, and its content in alluvial ore is very low, in order to extract gold from alluvial ore, an efficient and feasible beneficiation method and equally efficient beneficiation equipment must be used in order to obtain a good return. Alluvial gold washing production line is a production line for washing and extraction of alluvial gold ore. Alluvial gold washing production line generally consists of trommel screen, washing machine, jig machine, amalgamation cylinder, shaking table and other equipment.

Technological Process

Alluvial Gold Ore

In general, the river pebbles and other large stones in alluvial gold ore do not contain gold at all, but such stones occupy 20% to 80% of the alluvial gold ore, so in the early stage of alluvial gold washing, pre-screening such waste stones has a very important role in improving the effective working rate of the whole alluvial gold washing production line, so the first process of alluvial gold washing is sieving. Alluvial gold ore sieving can use trommel screen or vibrating screen, if the alluvial gold ore contains more sticky mud, the gold particles are easy to be wrapped by the sticky mud, in order to make most of the gold particles free out, the alluvial gold ore with high mud content must be washed, which is used in the washing machine.

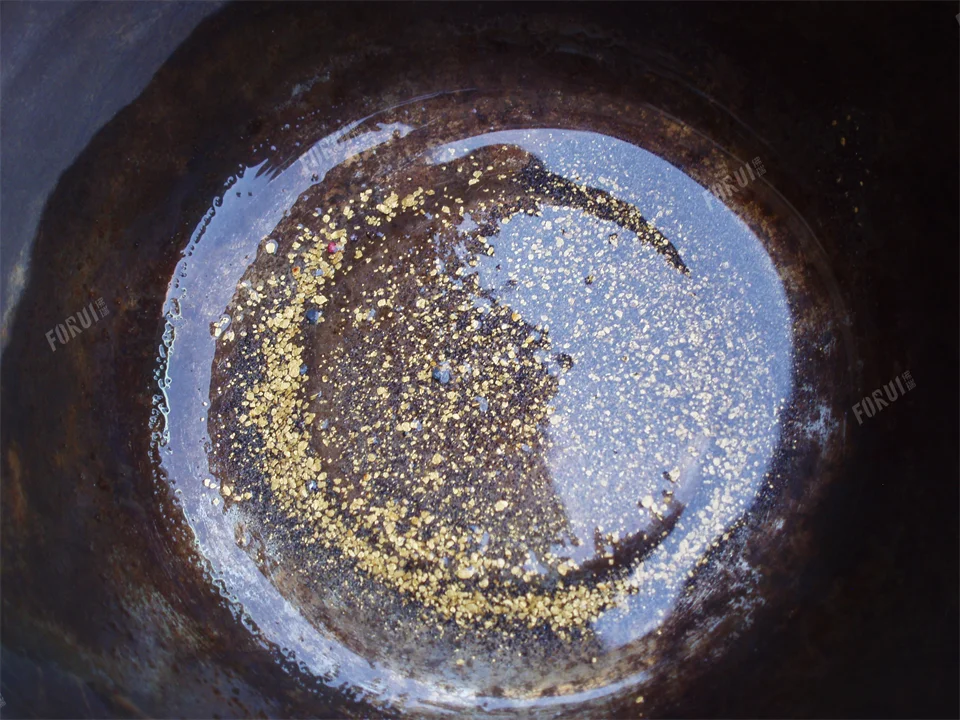

For the alluvial gold ore with more mud content is usually washed by trommel scrubber and screened at the same time, for the alluvial gold ore with less mud content can be directly into the gravity separation process after screening. Most of the gravity beneficiation process of alluvial gold ore adopts jigger as roughing equipment, and there are also cases of using ore dressing sluice box as roughing equipment. Alluvial gold ore with higher gold content is recommended to use jigger as rougher separation, because it can guarantee the highest recovery rate. Alluvial gold ore with lower gold content is recommended to use concentrator sluice box, which can guarantee the maximum processing capacity. After enrichment by jigger or sluice box, the alluvial gold coarse concentrate can be directly extracted from gold by selection equipment such as amalgamation cylinder or shaking table. Experimental video of alluvial gold ore beneficiation by jigger:

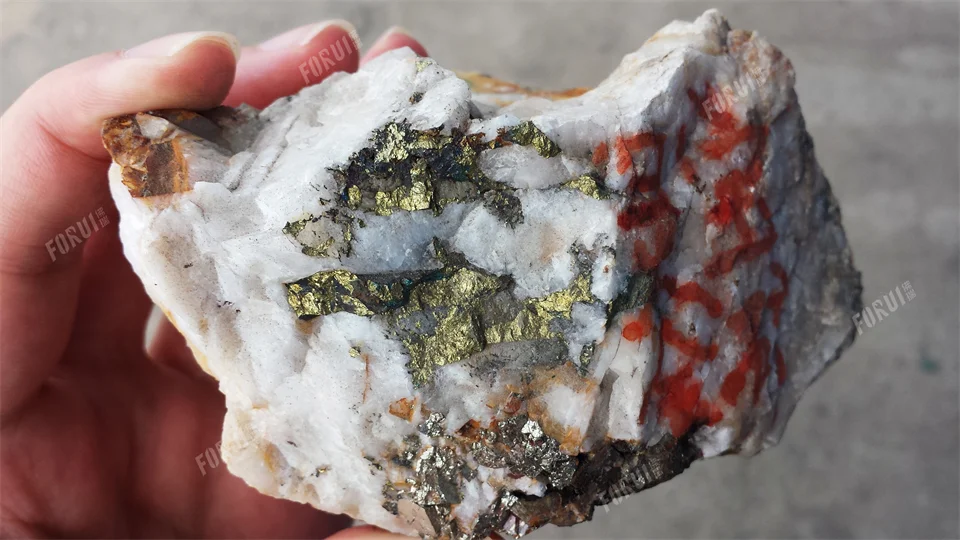

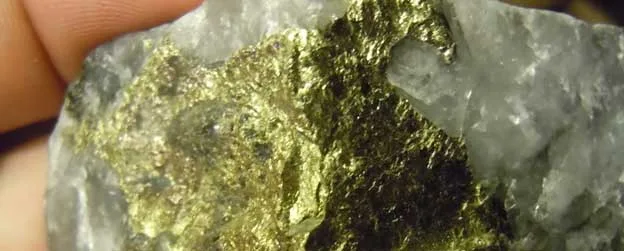

Fine-grained Dipping Quartz Veinstone Gold Ore

As shown above, this gold ore type belongs to the gold ore which is embedded in quartz veins in the natural gold state. But these natural gold is in fine grained form, even if visible gold can be seen, it is mostly in flake form, and fine grinding is necessary to make the gold grains to achieve monolithic separation. After fine grinding, mercury plates are set at the discharge end of the ball mill to pre-recover the coarse-grained gold as well as the bright gold that is ground into flakes. Since the mercury plate only recovers the coarse gold, while some of the fine gold is lost in the tailings, flotation sweeping of the tailings from the mercury plate is also required to maximize the recovery.

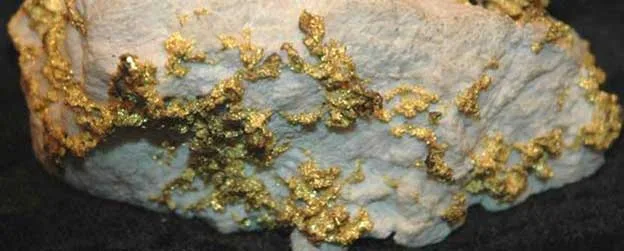

Coarse-grained Dipping Quartz Veinstone Gold Ore

As shown above, this gold mine belongs to the rock gold ore with natural gold embedded in quartz veins in coarse-grained state, and the beneficiation method of this rock gold ore is very simple. Because of the large size of the natural gold and the specific gravity difference with the vein, most of the gold can be recovered by gravity separation, and the tailings can enter the amalgamation barrel to further recover the fine-grained gold.

Sulphide Gold Ore

If the natural gold and sulfide, especially the sulfide iron ore dense symbiosis, sulfide iron ore is the carrier of gold, such gold ore in the beneficiation process will usually be sulfide will be selected at the same time, in order to guarantee the recovery rate. Thionite and other sulfides in the ore is mostly coarse-grained state, it has a very obvious specific gravity difference with the vein, so this type of gold ore beneficiation is also very simple. We can first recover the sulfides by gravity beneficiation, and then deep processing of the sulfides (concentrate) to extract the gold. Usually these sulphides are subjected to calcination or cyanidation processes to extract gold.

Product

- Xinjiang alluvial gold ore washing production line

Xinjiang alluvial gold ore processing production line work site video: Xinjiang alluvial gold ore washing production line using the process and production line configuration of trommel screen screening, sluice box roughing, jigger sweeping, amalgamating cylinder selection, to complete the daily processing of 3000 square alluvial gold ore processing tasks, the daily recovery of gold more than 900 grams, the washing effect is remarkable, the customer is very recognized by Forui Machinery alluvial gold ore washing production line.

- Sichuan alluvial gold ore washing production line

Sichuan alluvial gold ore washing production line adopts the process and production line configuration of trommel screen screening, jigger roughing and shaker selecting to complete the production task of processing 1500 square meters of alluvial gold ore per day and recovering more than 300 grams of gold per day, which is well reflected by customers.

- Inner Mongolia Gold Washing Production Line

Inner Mongolia Gold Washing Production Line adopts the process and production line configuration of trommel screen screening, trapezoidal jigger gravity separation and shaking bed selection, completing the production task of processing 500 square meters of alluvial gold ore per day and recovering more than 300 grams of gold per day, with remarkable washing effect and high evaluation from customers.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.