In incineration slag treatment projects, the production of eco-friendly sand is often regarded as the final and most visible outcome of the entire processing system. After metals are recovered, the remaining mineral fraction represents a large volume of material with potential reuse value in construction and infrastructure applications.

However, transforming slag-derived minerals into usable eco-friendly sand is not simply a matter of size classification. Moisture control plays a decisive role in determining whether the final product can be stored, transported, and utilized efficiently. In this context, dewatering screens are a critical yet sometimes underestimated component of incineration slag treatment systems.

Characteristics of Slag-Derived Sand and Moisture Challenges

Eco-friendly sand produced from incineration slag differs from natural sand in several important ways. Due to wet processing stages such as jigging, shaking tables, and water-based separation, slag-derived sand typically exits the system in slurry form with high moisture content. Common challenges associated with excessive moisture include:

- Difficulty in stockpiling and material handling

- Increased transportation cost due to added water weight

- Poor suitability for downstream applications such as brick making

- Risk of material segregation and instability during storage

- Difficulty meeting project or regulatory requirements for moisture limits

Without effective dewatering, the economic and practical value of eco-friendly sand is significantly reduced.

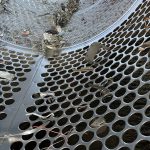

Working Principle of Dewatering Screens

Dewatering screens use high-frequency vibration combined with inclined screen surfaces to rapidly separate water from solid particles. Unlike conventional screening equipment focused on size separation, dewatering screens are specifically designed to maximize water removal while retaining fine particles. Key operating features include:

- High vibration acceleration to promote rapid drainage

- Specialized screen media that retain fine sand particles

- Inclined deck design to assist water flow and discharge

This design enables dewatering screens to achieve low residual moisture content in a continuous and stable manner.

Role of Dewatering Screens in Slag Treatment Systems

Final Moisture Control for Eco-Friendly Sand

The primary role of dewatering screens is to reduce the moisture content of slag-derived sand to a level suitable for storage and reuse. This step transforms slurry into a solid material that can be directly conveyed to stockpiles or storage silos. In many projects, dewatering screens are positioned downstream of hydrocyclones or classification units to perform final moisture reduction.

Integration with Water Recycling Systems

Dewatering screens also play a crucial role in closed-loop water circulation. The water removed during dewatering is collected and returned to sedimentation tanks or clean-water systems for reuse. This integration offers multiple benefits:

- Reduced freshwater consumption

- Lower wastewater discharge volumes

- Improved overall water balance control

- Enhanced environmental compliance

From a system design perspective, dewatering screens serve as a bridge between solid product handling and water management.

Improvement of Product Quality and Consistency

Uniform moisture content is essential for ensuring consistent product quality. Dewatering screens help achieve:

- Stable moisture levels across production batches

- Improved flowability of eco-friendly sand

- Better performance in downstream processing such as molding or mixing

This consistency is particularly important for applications in eco-brick manufacturing and infrastructure construction.

Impact on Storage, Transportation, and Utilization

Effective dewatering directly influences the commercial usability of slag-derived sand. Well-dewatered sand offers:

- Reduced transportation costs due to lower weight

- Easier handling with conventional conveyors and loaders

- Improved storage stability without excessive drainage or pooling

- Compatibility with standard construction material handling practices

In contrast, inadequately dewatered material often requires additional handling steps or extended drainage time, increasing operational complexity.

Engineering Considerations for Dewatering Screen Selection

Selecting the appropriate dewatering screen requires careful evaluation of several factors:

- Particle size distribution of the sand

- Required final moisture content

- Throughput capacity and system integration

- Screen media type and wear resistance

- Vibration intensity and structural durability

Improper selection may lead to material loss, excessive wear, or insufficient dewatering performance. Therefore, dewatering screens should always be selected as part of a complete system design rather than as isolated equipment.

Economic and Environmental Significance

From an economic standpoint, effective dewatering increases the marketability of eco-friendly sand and reduces downstream handling costs. Environmentally, improved water recovery reduces the demand for freshwater and minimizes discharge volumes.

These combined benefits make dewatering screens a key contributor to both project profitability and environmental sustainability.

Conclusion

Dewatering screens play a vital role in converting incineration slag slurry into usable eco-friendly sand. By effectively controlling moisture and supporting water recycling, they enable stable material handling and reliable downstream utilization.

With experience in slag treatment systems, Forui supports practical equipment selection and system design, helping projects achieve stable operation and consistent product quality.