Metal recovery is one of the core objectives in the resource utilization of municipal solid waste incineration slag. Incineration slag typically contains a considerable amount of metal components, ranging from large iron pieces to fine iron powder. If these metal materials are not effectively recovered, they not only result in resource losses but may also adversely affect the performance and applicability of downstream slag-derived products.

For this reason, magnetic separation plays a critical role in incineration slag treatment systems. Through proper configuration and multi-stage application, magnetic separation processes can achieve high metal recovery rates while ensuring stable and reliable system operation.

Why Multi-Stage Magnetic Separation Is Required in Slag Treatment

In practical engineering applications, metal recovery from incineration slag is rarely achieved through a single magnetic separation step. Instead, it is typically realized through a multi-stage magnetic separation process.

Primary Magnetic Separation: Front-End Iron Recovery and Equipment Protection

Primary magnetic separation is usually installed upstream of crushing equipment and is mainly used to recover large iron pieces.

Its main functions include:

- Preventing iron pieces from entering crushers and causing equipment damage

- Reducing crushing energy consumption

- Improving overall system stability and operational safety

Secondary Magnetic Separation: Iron Recovery After Crushing

After crushing, ferrous particles that were previously encapsulated within mineral material are liberated. Secondary magnetic separation targets this portion of iron and represents a key step in improving overall iron recovery efficiency.

Fine Magnetic Separation: Iron Powder Recovery

After screening or gravity separation, fine magnetic separation is commonly applied to recover iron powder and fine ferrous particles. Although individual particles are small, the cumulative recovery volume can be significant. This step also effectively reduces iron content in final slag products.

Eddy Current Separation: Non-Ferrous Metal Recovery

After ferromagnetic metals have been recovered, incineration slag usually still contains non-ferrous metals such as aluminum and copper. These metals are not attracted by static magnetic fields and are typically separated using eddy current separators under alternating magnetic fields. This process can be regarded as an extension of magnetic separation technology for non-ferrous metal recovery.

Common Magnetic and Metal Separation Equipment Used in Slag Treatment

According to particle size range and process requirements, commonly used magnetic and metal separation equipment in slag treatment includes:

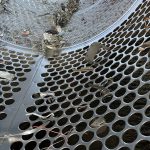

- Overband magnetic separators, used for recovering coarse iron pieces and large ferrous materials

- Drum magnetic separators, used for separating ferrous metals from medium-sized material streams

- Fine magnetic separators, used for recovering iron powder and fine ferrous particles liberated during crushing and liberation

- Eddy current separators, used for separating non-ferrous metals such as aluminum and copper after magnetic separation

By properly combining different types of magnetic and metal separation equipment, both ferrous and non-ferrous metals in incineration slag can be systematically recovered, meeting comprehensive requirements for recovery efficiency and final product quality.

Impact of Magnetic Separation on Overall System Performance

Efficient magnetic separation not only improves metal recovery rates but also has a positive impact on the entire slag treatment system, including:

- Reducing metal residues in mineral products

- Improving the performance of gravity separation equipment

- Reducing wear on crushing and screening equipment

- Enhancing the quality of eco-friendly sand and aggregate products

Magnetic Separation Parameters and System Optimization

The effectiveness of magnetic separation is closely related to equipment parameters and system layout, such as magnetic field strength, feed layer thickness, processing capacity, and coordination with other equipment.

Therefore, magnetic separation equipment should be configured as an integral part of the overall process design rather than being selected and operated as isolated units.

Economic and Environmental Significance of Metal Recovery

From an economic perspective, metal recovery directly increases project revenue. From an environmental perspective, reducing the amount of metal entering landfills helps improve the level of slag resource utilization.

Magnetic separation thus serves as a fundamental component of sustainable incineration slag treatment systems.

Conclusion

Magnetic separation plays an indispensable role in metal recovery from municipal solid waste incineration slag. Through properly designed multi-stage separation processes, high recovery efficiency and long-term system stability can be achieved. With experience in incineration slag treatment applications, Forui supports projects through process design, equipment supply, and technical guidance, helping slag treatment systems operate reliably over the long term.