Introduction

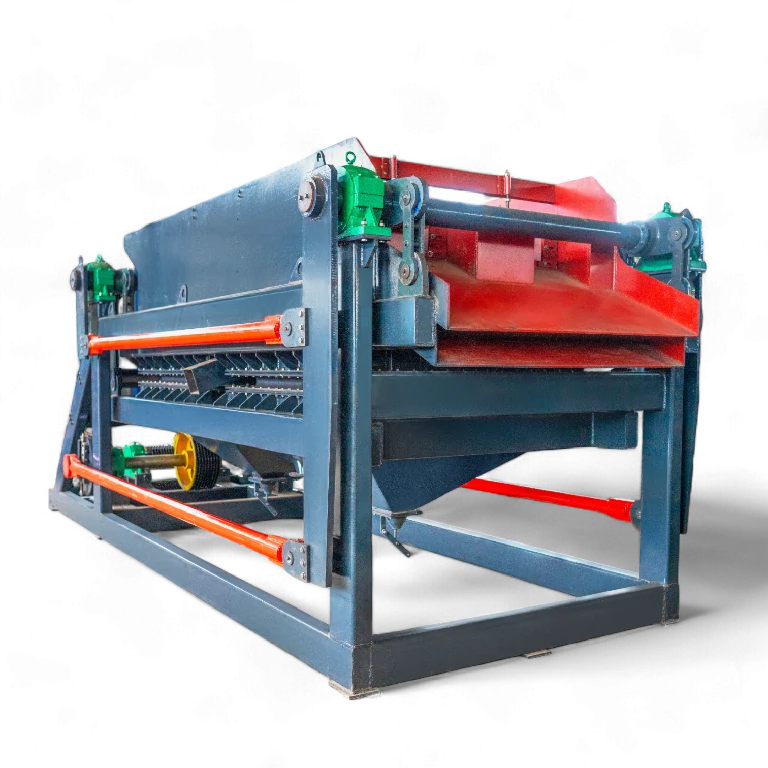

The compound double movable sieve jig is a kind of lever compound moving sieve jig. It can beneficiate multi-level minerals, double-acting up and down, and beneficiation of coarse and fine minerals at the same time. The thickness of the ore layer in the beneficiation tank can reach 1 meter, the selected particle size range is 1~50mm, and the output can reach 150 tons/hour. It is a high-efficiency concentrator.

Features

- It is convenient to adjust the stroke length and stroke times.

- Adjustable water supply system, effectively reducing water consumption.

- A wide range of feeding particle sizes, which is between 5-60mm.

- The output is large, and the processing capacity can reach 2000 tons/day.

- It adopts multi-level compound levers, up and down double action is balanced by force, energy-saving, and high efficiency.

- It can beneficiate the three grades of minerals in the upper and lower double layers, and the coarse ore-forming layer on the upper screen automatically serves as the cushion function. Mastering the thickness of the ore layer of the coarse concentrate can directly control the quality and productivity of the upper coarse concentrate and the lower fine concentrate. One piece of equipment can be used for the beneficiation of coarse and fine ore at the same time. The first level is the main beneficiation, the second level is the multiple beneficiations, and the third level is recycling and reuse. Multi-level simultaneous beneficiation can make the recovery rate higher.

- All levels of beneficiation tanks are equipped with observation windows to directly observe the process of layered mineralization. The observation of water flow, water pressure, jigging amplitude, and speed is beneficial to control the quality of mineral processing, production capacity, and recovery rate.

Structure

The structure of the composite double movable sieve jig machine mainly includes base frame transmission combination, upper three-level coarse ore beneficiation combination, lower three-level fine ore beneficiation combination, and sealing connection rubber components between the upper and lower layers.

Working Principle

The compound double movable sieve jig adopts the principle of lever mechanics and drives the lower three-level fine ore beneficiation combination through the base frame transmission combination, and the lower three-level fine ore beneficiation combination drives the upper three-level coarse ore beneficiation combination. So as to complete the beneficiation process of upper and lower compound double action.

The variable-speed power system drives the lever device to drive the sine wave rocker arm to make a sine wave motion. And the short connecting rod connection component drives the composite box to make a sine wave motion. At the same time, the rubber compound film of the inverting device is driven to open and close, thereby causing the medium water in the box to produce a wave of pushing and sucking.

Coupled with the self-hanging force of the mineral particles, the mineral particles produce a sinusoidal drift motion during the forward movement. The mineral particles with low density will gradually rush out with the water flow in the upper layer. While the dense mineral particles will gradually sink, fall into the lower blanking device. When the material has accumulated to a certain amount, it will be discharged from the electric control box through the electric switch valve.

Technical Parameters

| Model | Feeding Size(mm) | Capacity(T/h) | Power(KW) | Jigging Area(㎡) |

|---|---|---|---|---|

| FDX4-2 | 1-50 | 50-80 | 15 | 4 |

| FDX8-4 | 1-50 | 80-150 | 22 | 8 |

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.