Online Consultant

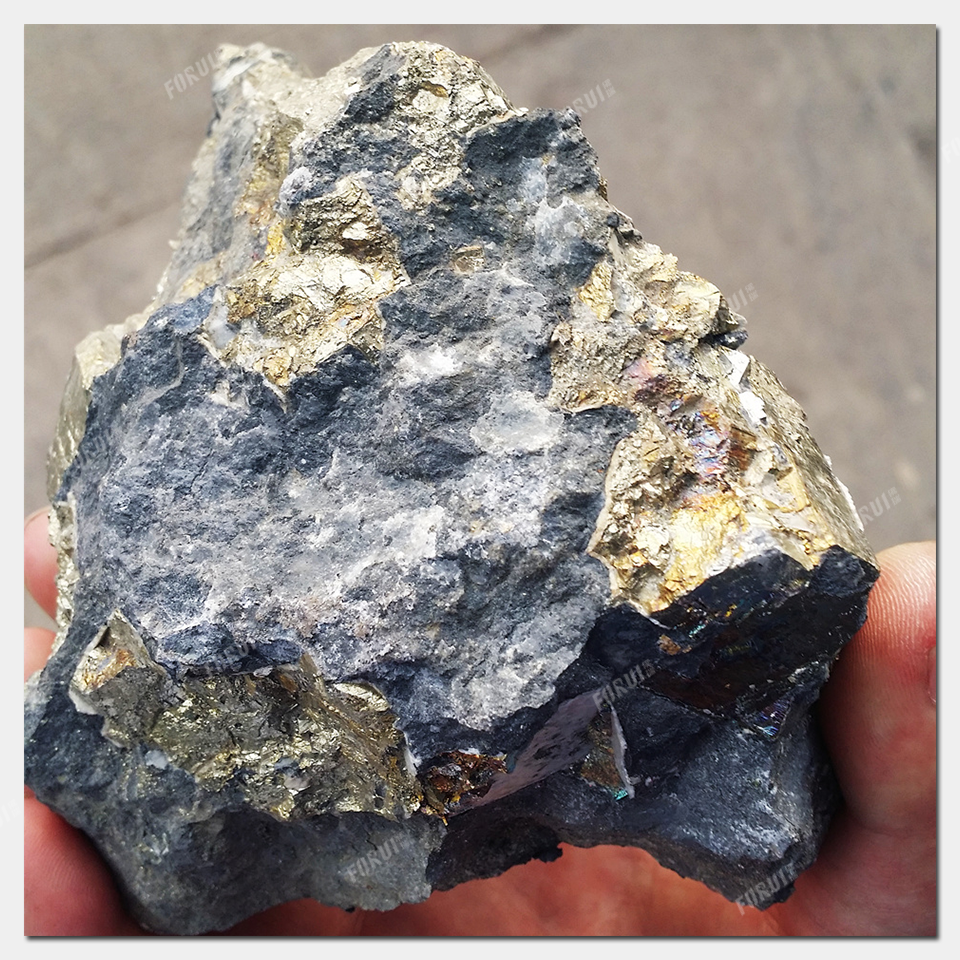

Sulfur iron ore beneficiation production line is mainly used to extract sulfur iron ore from the ore. The main equipment of the sulphur iron ore beneficiation production line includes crusher, fine crusher, rod mill, jigger, dewatering screen, silo, feeder, conveyor, etc.

Technological Process

The beneficiation of sulfur iron ore is mainly done by the method of gravity beneficiation, which is based on the specific gravity difference between sulfur iron ore and vein stones. The specific gravity of sulfur iron ore is 4.9-5.2, and the specific gravity of vein stones associated with sulfur iron ore mostly does not exceed 3.0, so there is an obvious specific gravity difference between sulfur iron ore and vein stones, which is easy to select. Moreover, the embedded particle size of sulfite in the ore is generally coarse, and a high degree of monomeric dissociation can be achieved by crushing or fine crushing, and then the high-grade sulfite concentrate can be produced by gravity beneficiation in the jigger.

Client Case

- Sulfur iron ore beneficiation production line

This sulfur iron ore beneficiation production line is to extract sulfur iron ore from sulfur iron ore. This production line adopts jaw crusher for coarse crushing, rod mill for fine crushing, trapezoidal jigger for gravity beneficiation, dewatering screen for dewatering and other equipment. The sulfite ore is hard and has 15-20% sulfur content. After processing by the sulfite production line, the sulfite concentrate contains 42.2% sulfur and the recovery rate is over 90%, and the indicators are approved by the customers.

- Coal-based sulfur iron ore beneficiation production line

This sulfur iron ore beneficiation production line is to extract sulfur iron ore from coal gangue, using jaw crusher coarse crushing, hammer crusher fine crushing, trapezoidal jigger gravity separation, linear dewatering screen dewatering process and equipment configuration to complete the task of extracting sulfur iron ore from high sulfur coal gangue, coal gangue contains 20-25% sulfur, jigger gravity separation concentrate contains 38-42% sulfur, recovery rate More than 90%, each beneficiation index is recognized by the customer. 3.

- coarse grained sulphur iron ore beneficiation production line for counterweight

The specific gravity of sulphur iron ore is large, in addition to being used in military, agriculture, chemical and other industries, it is also used in the counterweight industry. Coarse-grained sulphur iron ore is high quality counterweight material, such as Anhui region in China, where most of the sulphur iron ore is coarse-grained sulphur iron ore, which is very suitable for producing counterweight ore. This sulphide iron ore beneficiation line adopts the process and equipment configuration of coarse crushing by jaw crusher, screening by circular vibrating screen, gravity beneficiation by large particle jigger and downward moving jigger, and dewatering by dewatering screen. The plant accomplished the task of extracting coarse grained sulfur iron ore and fine grained sulfur concentrate sand at the same time. The specific gravity of raw ore is 3.6, the specific gravity of concentrate is 4.4-4.6, the recovery rate is over 90%, and the beneficiation index fully meets the customer’s requirements.

- Sulfur concentrate sand beneficiation production line

Sulfur concentrate sand beneficiation production line refers to the production line for producing sulfur concentrate sand, no matter the raw material is ore or gangue, through this beneficiation line, fine grain sulfur concentrate sand is obtained, which is used in agriculture as well as sulfuric acid and other industries. This processing line adopts the process configuration of coarse crushing by jaw crusher, fine crushing by rod mill, gravity separation by downward moving jigger and dewatering by dewatering screen. The production line has completed the task of extracting sulfur concentrate sand from ore and gangue with good beneficiation index, which is well received by customers.

In fact, another method of sulfur iron ore beneficiation is flotation, flotation method for sulfur iron ore beneficiation index is higher, but the equipment investment is huge, the production cost is higher, and there is also a certain harm to the environment. Therefore, in recent years, the flotation method in the field of sulfur iron ore beneficiation is used less and less, with the high speed development of gravity separation equipment and technology, gravity separation method has completely replaced the trend of flotation method.

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. If you have any questions, feel free to Contact Us.