Introduction

The roller crusher is also called double roll crusher. For roller sand making machine, it uses two motors to drive two pairs of roller shafts to squeeze and grind the material.

The roller crusher is suitable for crushing brittle block materials in cement, chemical industry, electric power, mine, metallurgy, building materials, refractories, coal mines and other industries. It has large feed size, adjustable discharge size, and can withstand crushing strength ≤160 MPa.

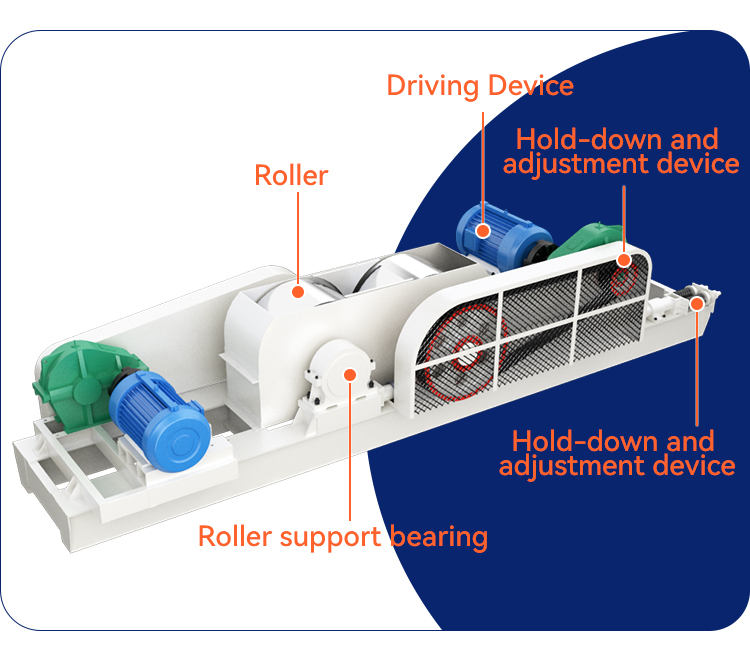

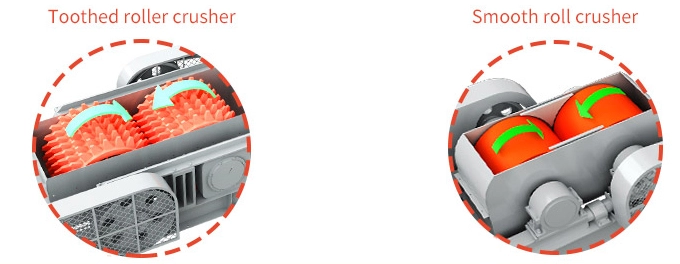

The roller crusher is a roller crusher which uses two rotating rollers to crush the material. It consists of motor, bracket, fixed roller, movable roller and safety spring. The roller surface is mostly smooth, the bearing of the movable roller can be moved along the frame, and the bearing can be removed and spit out when the particularly hard object falls in. Before normal operation, the gap between the two rollers should be adjusted with gaskets to ensure the crushing ratio. Suitable for crushing medium-breaking viscous materials.

Working Principle

The roller crusher is driven by two motors. The crushing effect of roller crusher is mainly crushing and grinding, which is mainly suitable for medium and fine crushing of medium and hard materials.

For roller crusher to obtain different strength products, the size of the discharge must be adjustable. In order to prevent the crusher from being damaged by iron, it is necessary to install a safety device. With the help of spring pressure, the spring force is enough to overcome the crushing force of the broken material under the normal working condition.

The gasket of different thickness is placed between the frame and the movable bearing. By changing the number of gaskets, the width of the discharge port between the two rollers can be adjusted to meet the requirements of different product granularity. After material discharge, the movable roll is reset under spring pressure. This is the mechanical discharge port adjustment and overload protection device (safety device).

Features

- Structure is simple and reasonable, operation cost is low, operation is stable, high efficiency and energy saving, crushing efficiency is high, discharge granularity is adjustable.

- Structure is simple, occupy space is small, operation and maintenance is convenient.

- Interior is equipped with dust-proof board, the sealing performance is good, the small material after crushing is avoided, the dust is less, the working noise is low, and the working environment is greatly improved.

- The roller crusher roller is equipped with replaceable wear-resistant liner, which adopts advanced wear-resistant material in China. It has the advantages of long service life, not easy to damage, convenient maintenance and so on. Continuous service life can reach more than one year, when wear is serious, remove the cover can be replaced. The maintenance quantity is small, the cost is low, this is any domestic other type crusher can not compare.

- The roller crusher is equipped with a safety protection device. When an unexpected metal iron piece enters the crushing chamber, the protective device acts and the iron piece leaks out of the equipment to run normally.

- Can be adjusted arbitrarily between 1 mm~ and 20 mm. After adjusting the roll seam according to the requirement of crushing particle size, the crushing particle size can be controlled reliably, all of which are discharged from the bottom of the crushing cavity with ideal particle size.

- In the process of further crushing, the energy consumption of grinding can be greatly reduced and the output can be increased.

Technical Parameters

| Model | Max Feed Size (mm) | Discharge Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|

| 2PG400×250 | 35 | 2~8 | 2-10 | 2×5.5 | 1.3 |

| 2PG400×400 | 35 | 2~8 | 5-12 | 2×7.5 | 2.3 |

| 2PG610×400 | 65 | 2~20 | 5-20 | 2×15 | 3.9 |

| 2PG750×500 | 75 | 2~25 | 10-40 | 2×18.5 | 9.5 |

| 2PG800×600 | 80 | 2~25 | 12-45 | 2×22 | 10.8 |

| 2PG1000×700 | 100 | 3~30 | 20-65 | 2×30 | 14.9 |

| 2PG1200×800 | 120 | 3~35 | 35-80 | 2×37 | 25.5 |

| 2PG1500×800 | 130 | 3~45 | 50-120 | 2×75 | 33.7 |

| 2PG1600×1000 | 150 | 3~50 | 60-140 | 2×90 | 41.2 |

Online Consultant

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation pieces of equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.