Do you know how to start using gravity beneficiations for gold extraction from placer mine? There are many methods of gravity beneficiation for gold ores.

Today, the following methods are mainly shared:

1) Gravity beneficiation of gold by sluice box

2) Gravity beneficiation of gold by shaking table

3) Gravity beneficiation of gold by mineral jig

Gravity beneficiation is used to separate minerals according to their relative density (commonly known as specific gravity). Mineral particles of different densities in moving media (water, air and heavy liquid) are subjected to fluid dynamics and various mechanical forces, resulting in suitable conditions for loose stratification and separation, thus separating ore particles of different densities.

Gravity beneficiation is one of the oldest and most common methods of gold extraction. In placer gold deposits, gold usually exists in the form of natural monomer gold, with a density of about 19 grams per cubic centimeter. The density difference between gold and gangue is relatively large. Therefore, gravity dressing is the most important, most effective and most economical method for processing placer gold deposits.

However, gravity beneficiation is rarely used alone in rock gold ore, and it is not used as part of the joint gold extraction process. Gravity dressing is generally used in the grinding and grading circuit to recover coarse particle monomer gold in advance by means of mineral jig, sluice box and shaking table and other equipment. This facilitates subsequent flotation and hydrogenation operations to obtain qualified gold concentrate.

The main equipments for gravity separation of gold ore is various types of sluice box, mineral jig and shaking table. According to the production characteristics of placer gold deposits, China has developed a lot of new gravity dressing equipments on the basis of learning advanced equipments from abroad. For example, sluice box for placer gold, mineral jig for placer gold, centrifugal gold separator, shaking table for placer gold, etc. They have achieved good results in gold concentrators.

The amalgamation method can be divided into inner amalgamation and outer amalgamation according to its production mode. Amalgamation of gold and heavy placer minerals is common in placer mines. In rock-gold mines, amalgamation is usually used as part of a joint process. It is used in combination with flotation, gravity dressing, cyanidation and so on, and is mainly used to capture coarse particle monomer gold.

1) Gravity Beneficiation for Gold extraction with sluice box

Gold extraction with sluice box is an ancient and still used gravity dressing method. Sluice box is the main equipment for gold selection. The sluice box is a long and narrow sluice box of wood (or steel) with an inclination Angle of 3° ~ 4°(not exceeding 14° ~ 16° at most).

Principle: after the slurry is fed into the sluice box from the head of the sluice box, under the combined action of water flow force, gravity (or centrifugal force) of mineral particles, friction force between mineral particles and the bottom of the sluice box, mineral particles of different densities are loosely stratified and separated. The mineral particles with high density become concentrate at the bottom of the trough, while the mineral particles with low density become tailings. Sluice box is an intermittent operation. When the concentrate is deposited to a certain height at the bottom of the sluice box, the feed can be stopped and the concentrate taken out.

The sluice box is divided into coarse sand sluice box and slime sluice box, the former is suitable for treating coarse grain material and the latter for treating fine grain material. The bottom of the coarse sluice box is equipped with bedding and baffle(the selection process is shown in the diagram below).

Coarse sluice box is the main equipment for gold ore dressing and is widely used on land and on gold mining ships. The large sluice box on the land is generally about 15 meters, and the one on the gold mining ship is generally 4 ~ 6 meters.

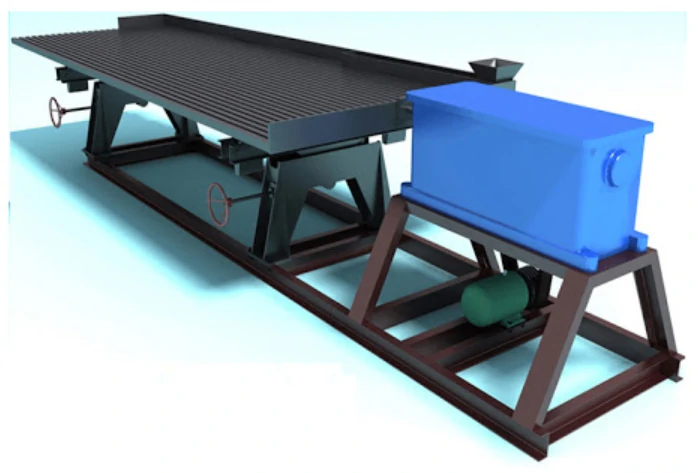

2) Gravity Beneficiation for Gold extraction with shaking table

Gold extraction with shaking table is a process of shaking table as the main equipment. The shaker is the equipment for ore dressing in horizontal medium flow, which is composed of bed surface and transmission mechanism. The bed surface is driven by the transmission mechanism for longitudinal reciprocating movement. The separation of minerals on the shaker is completed gradually in the reciprocating movement of the bed surface.

The main factors contributing to the movement of ore particles are the impact flow and differential movement of bed surface in addition to their own gravity. During the movement, the ore grains are subjected to stratification perpendicular to the bed surface and separation from the bed surface. The result of these two actions is that different ore grains are discharged from different sections of the bed surface.

3) Gold extraction with jigging

Gold extraction with jigging is a gold separation process with mineral jig as the ore dressing equipment. Mineral jig is a commonly used gravity dressing equipment, it has many types. At present, the majority of gold plants at home and abroad are diaphragm mineral jig.

The working principle of diaphragm jig is: when the eccentric transmission mechanism drives the diaphragm to reciprocate, the water in the jig room will flow through the vertical alternating pulsating water generated by the screen. The selected materials are given to the upper layer of the bed, and the bed ore and water constitute a pellet group system. When the flow of water shocks upward, the particles are in a loose suspension state. At this point, the ore particles of different weight and size settle at different speeds, and the coarse particles of large density (bed rock) settle in the lower layer. As the water flow drops, suction occurs and dense and small ore particles pass through the bed gap into the lower layer.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!