Municipal solid waste incineration generates a large volume of incineration slag containing ferrous metals, non-ferrous metals, and mineral aggregates. Without proper treatment, this material places long-term pressure on landfill capacity and environmental compliance. With appropriate processing and separation technologies, incineration slag can be transformed into valuable recyclable resources and eco-friendly construction materials.

We provide complete incineration slag treatment solutions, covering equipment supply, process design, system integration, and on-site implementation. Our solutions are engineered to achieve high recovery efficiency, stable operation, and low operating cost, while meeting modern environmental protection and resource utilization requirements.

1.High-Efficiency Metal Recovery

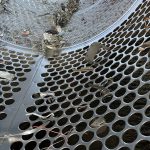

Through multi-stage crushing, screening, magnetic separation, gravity separation, and aluminum recovery technologies, ferrous metals, iron powder, copper, aluminum, and other valuable metals are efficiently recovered. Optimized equipment combinations ensure minimal metal loss and high product purity.

2.Eco-Friendly Sand Production

After metal recovery, the remaining mineral fraction is processed into eco-friendly sand suitable for eco-brick manufacturing and infrastructure applications. Controlled particle size distribution and low moisture content allow direct storage and downstream utilization.

3.Closed-Loop Water Circulation

The entire system is supported by a closed-loop water treatment and recycling circuit. Process water is continuously clarified, filtered, and reused, significantly reducing freshwater consumption and ensuring environmentally compliant operation.

4.Flexible and Scalable Design

Each project is designed according to slag characteristics, treatment capacity, site layout, and local environmental standards. Modular equipment configurations allow easy expansion and adaptation to different project scales.

*Scope of Supply and Services

- Process and layout design for incineration slag treatment plants

- Supply of core equipment, including crushers, drum screens, magnetic separators, jig machines, shaking tables, hydrocyclones, dewatering screens, and auxiliary systems

- On-site installation guidance, commissioning, and operator training

- Technical support throughout the project lifecycle

*Value Delivered

- Reduced landfill disposal volume and associated costs

- Improved recovery of ferrous and non-ferrous metals

- Stable production of reusable eco-friendly sand

- Lower water consumption and operating expenses

- Compliance with environmental and sustainability requirements

About Forui

With experience in incineration slag treatment applications, Forui supports practical system solutions focused on stable operation and long-term resource recovery. Support is provided through process design, equipment supply, installation guidance, commissioning, and technical support, helping projects move smoothly from implementation to stable operation.