In incineration slag treatment projects, questions about gravity separation equipment are frequently raised during process design. Jig machines and shaking tables are traditionally associated with mineral processing, so it is natural for project owners and engineers to ask whether these devices are truly necessary for slag treatment—or if magnetic separation alone is sufficient.

The answer is not universal. Incineration slag is not a conventional ore, but it does share certain physical characteristics with mineral materials. Whether gravity separation equipment is required depends on slag composition, target recovery objectives, and overall project goals. Understanding when gravity separation adds value—and when it does not—is essential for designing an efficient and economically sound slag treatment system.

Why Gravity Separation Is Considered in Slag Treatment

At first glance, incineration slag may appear unsuitable for gravity separation. Unlike natural ores, slag is a by-product with irregular composition, variable particle shapes, and mixed material origins. However, gravity separation is applied not because slag resembles ore, but because of the way valuable metals behave within the slag matrix.

After crushing and screening, many non-ferrous metals such as copper, brass, and stainless steel exist as liberated particles. These metals typically exhibit significantly higher density than surrounding mineral material. Gravity separation techniques take advantage of this density difference rather than chemical composition, making them technically applicable to slag treatment under certain conditions.

Limitations of Magnetic Separation Alone

Magnetic separation is highly effective for recovering ferrous metals, but its capability is inherently limited to magnetic materials. In practice, incineration slag often contains a notable quantity of non-magnetic metals, including:

- Copper and copper alloys

- Aluminum fragments (partially oxidized or non-magnetic forms)

- Stainless steel and mixed metal particles

If the recovery objective extends beyond iron, relying solely on magnetic separation will result in unavoidable metal losses. This is where gravity separation becomes relevant as a complementary process rather than a replacement.

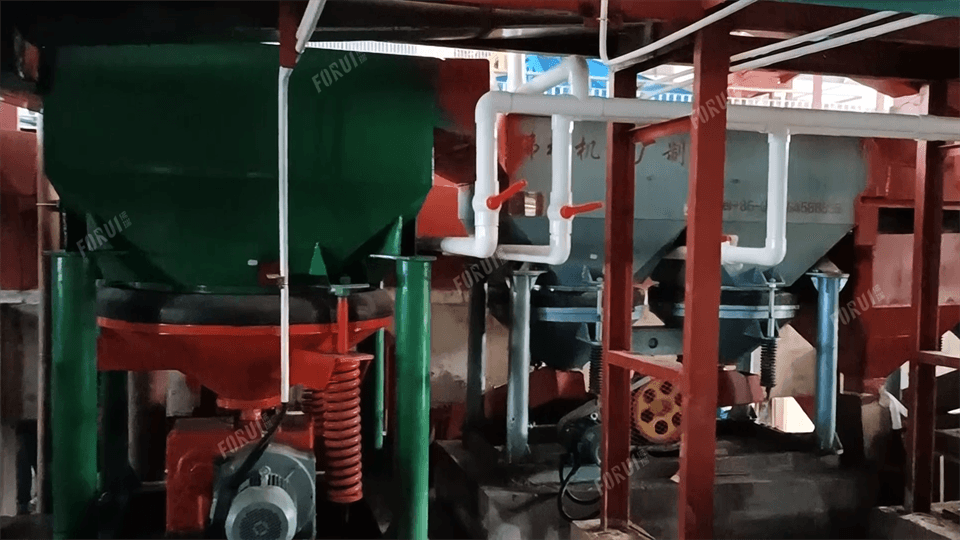

Typical Applications of Jig Machines in Slag Treatment

Jig machines are commonly used in slag treatment systems for coarse to medium particle sizes. Their pulsating water flow creates stratification based on particle density, allowing heavy metals to separate from lighter mineral fractions.

In slag applications, jig machines are typically positioned after crushing and screening stages, where particle size distribution has been reasonably controlled.

- Recovery of coarse non-ferrous metals

- Reduction of metal losses before final slag utilization

- Simple structure and relatively low operating cost

- Good tolerance to variable feed conditions

Jig machines are especially effective when slag contains visible metallic particles larger than several millimeters.

Role of Shaking Tables in Fine Metal Recovery

Shaking tables are primarily used for finer particle sizes and are often applied downstream of jig machines. Their inclined deck and differential motion allow precise separation based on subtle density differences.

In incineration slag treatment, shaking tables are typically used to recover:

- Fine copper particles

- Mixed non-ferrous metal concentrates

- Residual heavy particles remaining after jigging

Although shaking tables have lower capacity compared to jigs, their separation accuracy is significantly higher. For projects targeting maximum metal recovery or dealing with fine metal losses, shaking tables can play a valuable role.

When Gravity Separation Is Justified

Gravity separation equipment is not mandatory for every slag treatment project. Its inclusion should be based on clear technical and economic justification.

- Slag contains a measurable quantity of recoverable non-ferrous metals

- Metal prices or recovery targets support additional processing stages

- The project aims to minimize metal content in final slag products

- Fine metal recovery contributes significantly to overall project value

When Gravity Separation May Not Be Necessary

- Slag contains minimal non-ferrous metal content

- Recovery objectives focus primarily on iron removal

- Space, water availability, or operational complexity must be minimized

- The economic return does not justify additional equipment

In these situations, a simplified process based on crushing, screening, and magnetic separation may be more appropriate.

Engineering Considerations for Gravity Separation Integration

When gravity separation is included, its integration must be carefully planned. Factors such as feed size control, water balance, and downstream dewatering requirements must be considered as part of the overall system design.

Improper integration may lead to unstable operation, excessive water consumption, or limited separation efficiency. Gravity separation should therefore be evaluated at the system level rather than as a standalone upgrade.

Economic and Operational Perspective

From an operational standpoint, gravity separation increases process complexity but can also improve long-term returns. The recovered non-ferrous metals often have high market value, while reduced metal content in final slag improves its suitability for construction and infrastructure applications.

Balancing capital cost, operating cost, and recovery benefit is essential when deciding whether to adopt gravity separation equipment.

Conclusion

Gravity separation equipment such as jig machines and shaking tables can add measurable value to incineration slag treatment when applied under the right conditions. Their role is not to replace magnetic separation, but to complement it by improving non-ferrous metal recovery and reducing residual metal content in final slag products.

With practical experience in slag treatment applications, Forui supports project-specific process evaluation and equipment configuration, helping clients determine whether gravity separation is technically and economically justified, and ensuring stable operation and efficient resource recovery over the long term.