Overview

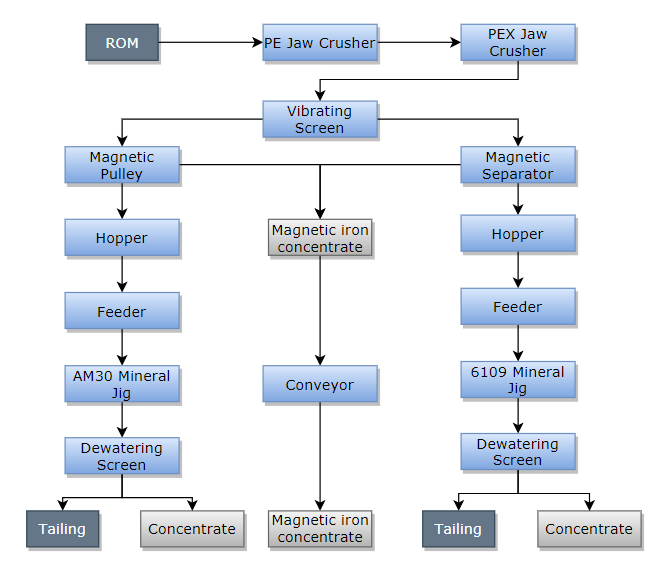

The beneficiation process in this process is divided into two parts, the first part is the magnetic beneficiation part, and the second part is the gravity beneficiation part. Magnetic beneficiation is mainly used to recover the magnetite part of magnetite and limonite symbiosis ore with higher magnetic permeability, and gravity beneficiation is mainly used to process limonite with lower magnetic permeability in the magnetite and limonite symbiosis ore section.

Introduction to the Beneficiation Process of the Symbiotic Ore of Magnetite and Limonite

1. Crushing Process

In the crushing process, two jaw crushers are used to crush the ore in two stages, and the product is ore materials below 30mm.

2. Screening Process

A jaw crusher is used to crush the ore, and most of the final product of crushing is granular ore, and also contains a certain proportion of powdered ore. After being sieved by a vibrating screen, it is divided into two particle sizes: 0-8mm and 8-30mm.

The screening equipment adopts a circular vibrating screen with simple structure and convenient operation. It has the characteristics of energy saving, high efficiency and high screening efficiency. It is an ideal equipment for screening ore.

3. Beneficiation Process

The beneficiation process in this process is divided into two parts, the first part is the magnetic beneficiation part, and the second part is the gravity beneficiation part. Magnetic beneficiation is mainly used to recover the magnetite part of magnetite and limonite symbiosis ore with higher magnetic permeability, and gravity beneficiation is mainly used to process limonite with lower magnetic permeability in magnetite and limonite symbiosis ore section.

3.1 Magnetic Beneficiation

Magnetic beneficiation uses magnetic pulleys and dry magnetic separators. Magnetic pulleys are used to process large particles (8-30mm) of ore, and dry magnetic separators are used to process small particles of powdery (0-8mm) ore. Qualified magnetite concentrate can be obtained after beneficiation by magnetic pulley and dry magnetic separator, and then directly transported to the magnetite concentrate field by conveyor.

3.2 Gravity Beneficiation

The gravity beneficiation process uses AM30 jig and 2LTC-6109/8T trapezoidal jig. The AM30 jig machine is used to process large particles of weak magnetic iron ore of 8-30mm, and the 2LTC-6108/8T jig machine is used to process small particles of weak magnetic iron ore of 0-8mm. The jig machine has strict requirements on the particle size of the feed material. Therefore, after screening strictly according to the feed size of the jig machine, it then enters the beneficiation process. Such an operation is extremely important for improving the beneficiation index of the jig machine. Meaning.

According to the processing capacity of 50 tons per hour, the configuration of two AM30 jig machines and one 2LTC-6109/8T jig machine can meet customer requirements.

4. Dehydration Process

The beneficiation process of the jig machine needs water, so the concentrate and tailings produced by the jig machine contain more water, which will affect the transportation of the concentrate and tailings. Therefore, the Forui Machinery Factory also designed a dehydration process to remove excess water from the concentrate and tailings of the jig. The dehydration process can not only reduce the water in the minerals, but also return the excess water to the water circulation system, which can save water and reduce the cost of mineral processing.

5. Delivery Process

The concentrate and tailings produced by magnetic separation do not have too much moisture and can be directly transported to the concentrate and tailings field by a simple belt conveyor. There is a lot of water in the concentrate and tailings produced by the jig, but after being dehydrated by the dewatering screen, it can also be transported by a belt conveyor. Therefore, the entire transportation process adopts a belt conveyor with a simple structure and convenient operation.

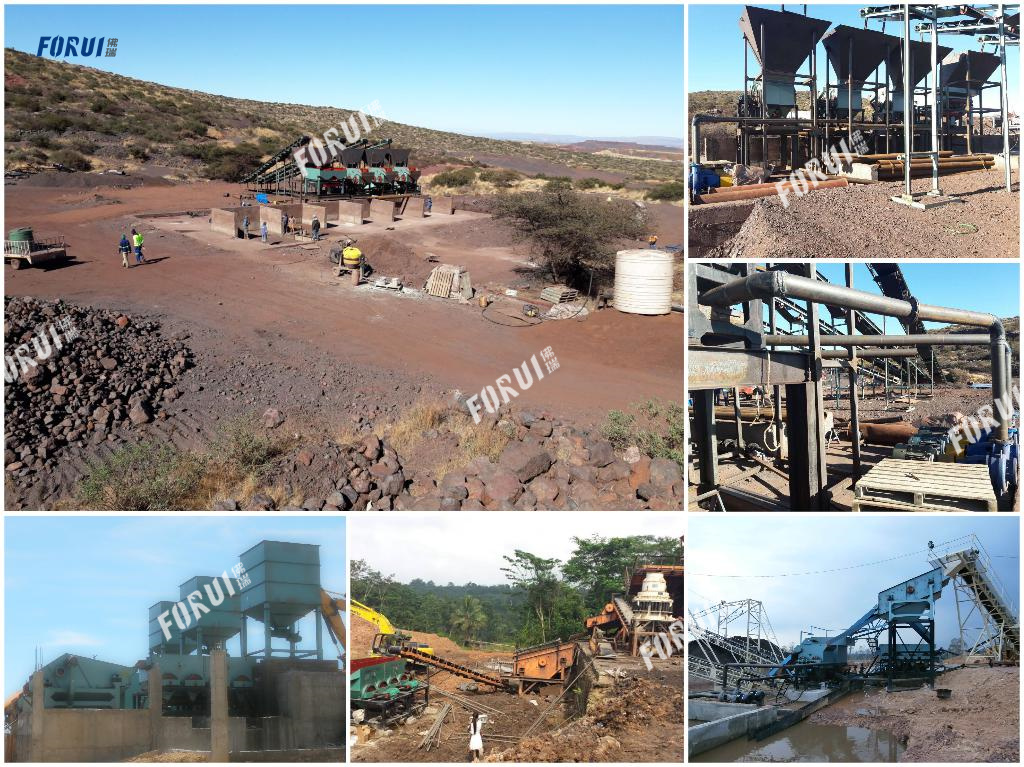

Projects

Ferrous Metal Ore Beneficiation Projects

Gold and Diamond Beneficiation Projects

Gold Beneficiation Projects

Non-ferrous Metal Ore Beneficiation Projects

Non-ferrous Metal Ore Beneficiation Projects

Non-metal Ore Beneficiation Projects

Smelting Slag Processing Projects

Smelting Slag Processing Projects

Gongyi Forui Machinery Factory is a professional manufacturer of mineral jigs, magnetic separators, vibrating screens, dewatering screens, and other beneficiation equipment. We have a professional beneficiation test platform, which can carry out beneficiation experiments for customers free of charge, and design the beneficiation process and equipment configuration according to the actual situation. Welcome customers to visit our factory and purchase equipment.

If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com