In gravity separation of fine and medium-sized heavy minerals, the shaking table remains one of the most effective tools when separation accuracy matters more than throughput. However, the performance of a shaking table depends far more on how it is operated than on the machine itself. Many plants install shaking tables but fail to achieve stable recovery or clear separation because operating conditions are not properly controlled.

This article summarizes practical operating methods that improve shaking table results in real processing plants, with emphasis on feed preparation, parameter adjustment, and on-site optimization.

1. Feed Conditions Determine the Upper Limit of Performance

A shaking table works best under thin-bed and laminar flow conditions. For this reason, unstable or poorly prepared feed quickly limits separation efficiency. To achieve reliable performance, focus on the following:

1. Particle size control: A narrow size distribution allows consistent response to deck motion. Pre-classification using screens, hydrocyclones, or classifiers can significantly improve shaking table efficiency.

2. Pulp density stability: In most gravity separation applications, a slurry concentration of about 15–30% solids provides a good balance between stratification and transport.

3. Clay and slime removal: Clay-coated particles tend to move as agglomerates and prevent proper separation. Washing or desliming before the shaking table is essential when clay content is high.

In practice, improving feed conditions often delivers greater benefits than repeated mechanical adjustments on the table.

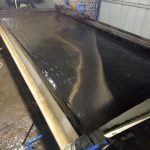

2. Observing the Deck Is Part of the Operation

One advantage of a shaking table is that the separation process is fully visible. Operators should use the deck surface as a diagnostic tool rather than relying only on instrument readings.

A well-adjusted shaking table usually shows a loose and evenly distributed bed, clear separation zones from heavy to light minerals, and stable forward movement of heavy particles toward the concentrate end. When these features disappear, the table indicates that correction is required.

3. Matching Stroke and Frequency to the Material

Stroke length and frequency control the acceleration applied to particles and strongly influence stratification behavior. Coarser particles typically respond better to larger strokes that loosen the bed, while finer particles require higher frequencies to increase stratification cycles.

Excessively low acceleration results in poor separation, while excessive acceleration may scatter particles and reduce directional control. Effective operation therefore requires balancing stroke and frequency based on observed particle movement rather than fixed settings.

4. Controlling Water Flow and Deck Inclination

Water flow and deck inclination govern lateral particle movement and directly affect concentrate quality. Too much water may wash fine heavy minerals into tailings, while too little water limits the removal of light gangue and lowers concentrate grade.

Steeper deck angles often favor capacity during roughing, while gentler slopes improve separation accuracy during cleaning. Adjustments to water flow and slope should be coordinated because changing one parameter influences the effect of the other.

5. Maintaining a Stable Feed Rate

Feed rate stability is often underestimated. Even well-adjusted shaking tables perform poorly under fluctuating feed conditions. Excessive feed rate thickens the bed and reduces stratification efficiency, while insufficient feed rate prevents formation of a stable separation zone.

Consistent and uniform feeding keeps the shaking table operating in a predictable regime and makes fine parameter adjustments meaningful.

6. Practical Use of the 6S Shaking Table

The 6S shaking table is widely used due to its stable mechanical structure and wide particle-size applicability:

- Coarse sand: approximately 0.5–3 mm

- Fine sand: approximately 0.074–0.5 mm

- Slime material: down to about 0.037 mm

Its advantage lies in predictable response to operational adjustments. When positioned after jigs or spiral concentrators, the 6S shaking table often improves final concentrate grade and overall recovery by refining intermediate products.

7. Treating the Shaking Table as a Dynamic Process

No shaking table operates under constant conditions for long periods. Ore characteristics, upstream performance, and feed composition inevitably change. Successful plants treat shaking table operation as a continuous optimization process, combining regular observation, small incremental adjustments, and operator experience.

Conclusion

A shaking table is not a plug-and-play device. Its effectiveness depends on the interaction between feed quality, motion parameters, water control, and visual indicators on the deck. When operated correctly, a shaking table delivers stable recovery, clear separation zones, and high-quality concentrates, even in fine-grained gravity separation applications.

About Forui

Forui Machinery specializes in gravity separation equipment and mineral processing solutions for heavy minerals such as tin, tungsten, tantalum–niobium, and fluorite. With extensive project experience in different ore types and operating conditions, Forui focuses not only on equipment manufacturing, but also on helping customers achieve stable and repeatable separation performance in real production environments.

Through practical process design, reliable shaker table manufacturing, and on-site application support, Forui Machinery assists mining and mineral processing plants in improving recovery, concentrate quality, and long-term operational stability.