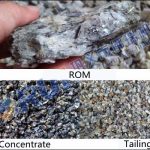

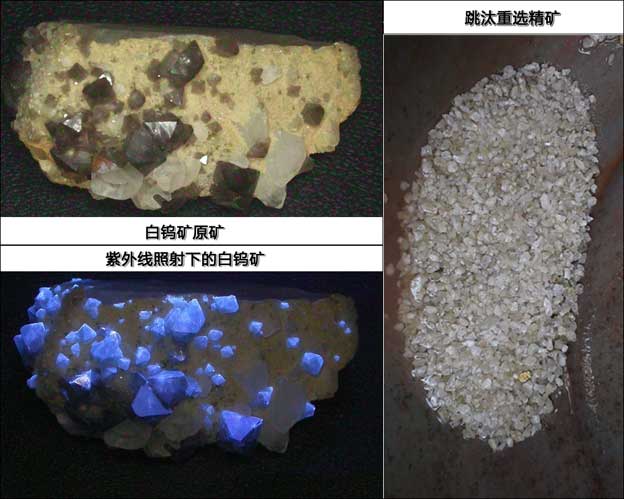

Tungsten ores are mainly divided into wolframite and scheelite. Wolframite, also known as iron–manganese tungstate, is the most important raw material for tungsten production.

In current industrial practice, wolframite processing mainly relies on gravity separation, combined with particle size classification, stage grinding, and separate fine slime treatment. This process route is mature and widely applied.

1. Key Beneficiation Characteristics of Wolframite

From the perspective of process design and equipment selection, wolframite shows the following characteristics. Wolframite has a high specific gravity of about 7.2–7.5, much higher than quartz and feldspar, which makes gravity separation highly suitable. It shows a wide particle size distribution, occurring as coarse particles (millimeter or even centimeter size) as well as fine and very fine fractions, which requires strict classification and stage separation. Due to its brittle nature, wolframite easily generates fine slimes during crushing and grinding, and poor process control may lead to metal losses. In addition, quartz vein deposits are usually thin, and coarse fractions often contain a high proportion of waste rock, making early waste rejection necessary.

These characteristics determine the basic principle of wolframite processing: gravity separation as the main method, clear size classification, early recovery of liberated particles, and separate treatment of fine slimes.

2. General Process Concept for Wolframite Processing

In industrial production, wolframite processing usually adopts a combination of roughing, main gravity separation, and fine slime treatment. Gravity separation runs through all main size fractions and plays a key role in tungsten recovery.

The purpose of the roughing stage is not to increase concentrate grade, but to remove waste rock as early as possible, reduce throughput, and prepare suitable particle sizes for further separation.

3. Roughing and Pretreatment

The roughing stage usually includes washing, crushing, desliming, and necessary manual or mechanical pre-concentration. When conditions allow, jigging or hand sorting of coarse particles can recover liberated wolframite early and reduce the load on the grinding stage.

4. Main Gravity Separation Process

4.1 Strict Size Classification

Before gravity separation, the ore must be classified into coarse, medium, and fine size fractions. Different gravity equipment and operating parameters are selected for each size range to avoid poor separation caused by mixed-size feeding.

4.2 Jig Separation for Coarse and Medium Sizes

Jig machines are widely used for coarse and medium wolframite recovery due to their large capacity, stable operation, and good adaptability. Jig tailings are usually not discarded directly, but sent to regrinding or further separation depending on tungsten content.

4.3 Shaking Table Separation for Fine Sizes

For fine particles and reground material, shaking tables remain an effective gravity separation method. Through multi-stage table separation, concentrate, middlings, and tailings are produced. Middlings return to grinding to form a closed circuit and improve overall recovery.

5. Separate Treatment of Fine Slimes

Fine slimes below 0.075 mm are generated during crushing and grinding. Although their yield is low, tungsten grade is often relatively high. If these slimes are discharged directly, significant tungsten losses may occur.

Therefore, mature wolframite processing plants usually set up independent fine slime separation circuits, using classification and fine gravity separation to recover tungsten.

6. Practical Gravity Separation Guidelines

Successful wolframite gravity separation depends on recovering coarse liberated particles as early as possible, while keeping grinding focused on mineral liberation rather than excessive size reduction. Gravity separation equipment must be selected and operated according to specific particle size ranges to maintain stable separation conditions. In addition, fine slimes require dedicated handling and recovery circuits to minimize tungsten losses. Together, these measures form a stable and cost-effective gravity separation system centered on jig machines and shaking tables.

Conclusion

Wolframite processing is dominated by physical separation. With proper size classification, stable gravity separation equipment, and effective fine slime control, reliable recovery and controlled operating costs can be achieved without complex chemical processes.

Forui Machinery specializes in gravity separation and provides integrated jig and shaking table solutions for wolframite processing based on ore characteristics and capacity.