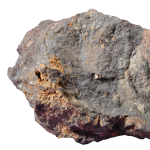

At a certain moment each day, municipal sanitation workers collect household waste in an orderly manner and transport it by garbage trucks to municipal waste-to-energy incineration plants. When mechanical arms feed various types of household waste into the incinerator, incineration slag gradually takes shape. As the final residue of the waste incineration process, slag becomes visible and is then transported by dump trucks to designated slag treatment project sites.

How does this incineration slag, once delivered to the treatment site, gradually transform into reusable and environmentally friendly materials?

1. Coarse Slag Sorting System

Incineration slag is fed into the system by a grab crane. Through a rotary drum screen, electromagnetic separators, and crushers, the slag is classified into coarse and fine fractions. Ferrous materials are preliminarily separated, facilitating subsequent cyclic magnetic separation and crushing processes. At the same time, unburned residues in the slag are removed, ensuring and improving the separation efficiency of downstream processes.

2. Iron Slag Separation System

Coarse and fine slag are conveyed separately to the next stage. Electromagnetic separators lift ferrous materials to the surface of the slag, followed by secondary magnetic separation to transfer iron metals to crushers for size reduction. The crushed metals are then screened by a rotary drum screen, producing recovered iron blocks as final products.

3. Iron Powder Recovery System

Slag conveyed by another conveyor is sent to a dedicated slag crusher for further crushing.

Iron powder and slag are finely screened through a rotary drum screen. The preliminarily recovered iron is further purified by magnetic separators and stored separately. The remaining iron-bearing slag is processed by jig machines combined with secondary magnetic separation, achieving an iron powder recovery rate of up to approximately 98%, significantly enhancing resource utilization efficiency.

4. Metal Separation System

Metal-bearing materials undergo primary and secondary separation using jig machines. The remaining slag is further processed by shaking tables, allowing most non-ferrous mixed metals to be recovered and stored separately. Water containing small amounts of copper sand is repeatedly circulated back into the crusher, forming a closed-loop process within the system.

5. Aluminum-Containing Separation and Re-Separation System

The aluminum separation and re-separation system consists of three recovery lines. Two lines carry out preliminary separation using rotary drum screens and aluminum separators. The remaining slag undergoes cyclic reprocessing through crushers, jig machines, rotary drum screens, and aluminum separators, ensuring the full recovery of copper, aluminum, and other valuable metals with minimal loss.

6. Eco-Friendly Sand Preparation System

After metal separation, the remaining slag slurry is subjected to water–sand separation through rotary drum screens, hydrocyclones, and dewatering screens. Once dewatered, the eco-friendly sand is directly transferred to the sand storage area for subsequent production of eco-bricks and various infrastructure construction materials.

7. Water Circulation Treatment System

In the water circulation system, clean water is supplied from the clean-water tank to crushers and shaking tables. Process water then flows into the collection tank. After sedimentation, the slurry is treated by a filter press. The clarified water is returned to the clean-water tank for reuse, while fine sludge and sediments are discharged, achieving efficient water recycling that is both economical and environmentally sustainable.

8. Finished Product Zoning and Storage

Recovered products are stored in designated areas according to type, including iron blocks, iron powder, copper, aluminum, and eco-friendly sand.

Conclusion

The above process represents a complete incineration slag treatment solution. By integrating advanced separation technologies and closed-loop water circulation systems, incineration slag is effectively transformed into valuable recyclable resources. This process not only improves resource recovery rates but also supports sustainable development and environmental protection goals, making it an essential component of modern solid waste management systems.