Introduction

The chemical composition of magnetite is Fe3O4. The crystals are oxide minerals in the equiaxed crystal system. The crystals are often octahedrons and rhombohedral dodecahedrons, and their aggregates are dense block or granular. The color is iron black, with black streaks, metallic luster or semi-metallic luster, opaque, no cleavage, Mohs hardness 5.5-6, specific gravity 4.8-5.3. It has strong magnetism and becomes hematite or limonite after oxidation.

The extraction of iron ore by magnetic separation has many advantages such as energy saving, high efficiency and high beneficiation index. Especially for the beneficiation of magnetite, magnetic separation is almost the only method of beneficiation. Magnetic separation is a separation method that uses the difference in magnetic permeability between minerals. It has been applied earlier in the history of beneficiation, and it also occupies an extremely important position in the field of iron ore beneficiation.

Magnetite magnetic separation process

Reasonable magnetic separation process and equipment configuration are very important to the beneficiation of magnetite. As a professional manufacturer of beneficiation equipment, Forui Machinery today will share with you the iron ore magnetic separation production line and magnetic separation process.

Magnetic separation is suitable for processing iron ore with good magnetic permeability, such as magnetite. For large, medium, and fine-grained iron ore beneficiation, it has corresponding magnetic separation equipment, and different beneficiation processes and equipment configurations can be designed according to actual conditions.

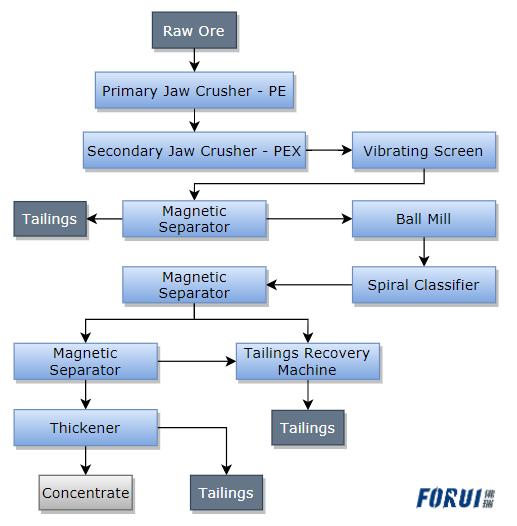

Generally, for the beneficiation of various types of magnetite, under the premise of reasonable magnetic separation process design and scientific equipment configuration, the concentrate grade can reach more than 63%, and the recovery rate can reach more than 90%. The following is a flow chart of a magnetic separation process designed by Fory Machinery.

The raw ore is crushed twice, and then the material is sent to the screening process. Through the screening process, the material is divided into two sizes of +30mm and -30mm. The ore larger than 30mm enters the fine crushing and crushed again, and the ore smaller than 30mm enters the dry magnetic separator for pre-selection.

The main function of the dry magnetic separator is to pre-select large-particle ore, which can discard a large amount of waste rock and low-grade ore. The pre-selection process is suitable for magnetite with coarse-grained distribution and uneven distribution of iron minerals in the ore. After that, the coarse concentrate from the dry magnetic separator is sent to the silo, and an electromagnetic vibrating feeder is set under the silo to evenly send the coarse concentrate to the ball mill for ore grinding.

The ground material enters the magnetic separation process after being classified by the classifier. The magnetic separation process is divided into three stages. The first stage is a roughing process, with a high magnetic field strength, which is used to recover most of the iron minerals in the grinding products. The second stage is the selection process, with the main purpose of improving the taste. Therefore, the second stage of magnetic separation can obtain a large part of the fine iron powder, and the tailings still contain a certain amount of iron minerals without monomer dissociation.

Therefore, the tailings produced in the second stage need to be beneficiated again, and then go through the grinding and grading process again, and then re-enter the magnetic separation process. The setting of this process is very helpful to improve the grade of concentrate and the recovery rate of the whole process. It is a necessary process for any large-scale iron ore magnetic separation plant. Finally, the concentrate after magnetic separation is sent to a thickener for concentration or into a sedimentation tank to settle to obtain the final concentrate.

Magnetite magnetic separation equipment

The equipment needed in the iron ore magnetic separation plant is mainly crushers, vibrating screens, dry magnetic separators, ball mills, classifiers, magnetic separators, tailings recovery machines, etc. The above process flow is only suitable for the beneficiation of magnetite and is suitable for the beneficiation of weakly magnetic iron ore. For the beneficiation of weakly magnetic iron ore, a strong magnetic separation process needs to be designed.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. We can design and manufacture professional iron ore processing equipment for you. Welcome to visit our company. We are dedicated to serving you! If you need equipment quotation and process flow, please feel free to Contact Us:

- Whatsapp: +8618026978087

- Email: asa.guo@foruimining.com