Why Bed Stability Defines Concentrate Grade and Recovery

In jigging separation, the bed is where separation actually happens inside a jig machine. While stroke, frequency, and water flow are often discussed as primary operating parameters, their real function is to create and maintain a stable jig bed. Once the bed condition is correct, separation in a mineral jig becomes repeatable, and both concentrate grade and recovery can be controlled more reliably.

How the Jig Bed Forms and Functions

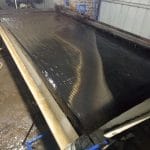

A jig bed is not a fixed layer. It is a dynamic structure formed by feed material, pulsating water, and—where underscreen discharge is used—an artificial bedding layer inside the jig machine. During each pulsation cycle, the bed loosens and re-compacts, allowing particles to rearrange according to density.

Effective separation in a mineral jig depends on whether this cycle consistently produces clear stratification. When bed resistance and pulsation energy are balanced, heavy particles migrate downward at a controlled rate while light particles disengage upward. The result is a stable separation interface and predictable product quality from the jig machine.

Jig Bed Type

In a jigging system, the jig bed is generally divided into two parts: the natural bed and the artificial bed. The natural bed is formed by the feed material itself under pulsating water flow, and its thickness and structure continuously change with feed characteristics and operating conditions in the mineral jig.

The artificial bed, by contrast, is intentionally installed using steel balls or ceramic balls as bedding material. Its function is to stabilize bed resistance and regulate the discharge path of heavy minerals, which is especially critical in underscreen-discharge jig machines.

Based on Forui’s long-term field experience with jig machines used in gold, tin, and fine heavy-mineral applications, the use of an artificial bed provides a more stable bed structure, a more uniform void distribution, and improved consistency in concentrate grade.

Jig Bed Condition Indicates Mechanical Issues

The objective of bed control in a jig machine is not to maximize looseness or compactness, but to keep bed resistance within a range that allows sufficient stratification time while maintaining controlled particle migration.

Non-uniform bed behavior—where some areas appear tight while others are overly loose—is often misinterpreted as an operating problem. In practice, it frequently points to mechanical causes such as uneven screen wear, improper leveling, localized blockages, or uneven feed distribution within the mineral jig.

In these cases, further adjustment of stroke, frequency, or water flow rarely solves the issue. Restoring mechanical symmetry and uniform flow conditions is usually a prerequisite before meaningful jig bed control can be re-established.

Bed Control as a Stability Strategy

Jigging is often described as a simple gravity process, but stable operation of a jig machine depends on continuous control of bed behavior. The jig bed reflects the combined effect of ore characteristics, machine condition, and operating settings.

When the bed remains stable and repeatable, the mineral jig becomes tolerant to moderate feed variations and delivers consistent separation performance. From a plant-operation perspective, effective bed control is less about constant adjustment and more about maintaining a system that naturally returns to a stable operating state.

With extensive on-site commissioning experience in jigging operations, Forui’s technical team helps customers achieve reliable and sustainable separation performance from their jig machines in actual production.