1 Introduction

If you have a gold mine with a gold content of about 2g/m³, then you can get 6 ounces of gold in one day. Calculated according to the current international gold price, you will get an income of 10498.8 US dollars, excluding labor costs, your daily net profit is 10,000 US dollars. Are you very excited now?

Let me share with you how to extract gold from gold mines efficiently.

2. Equipment for Extracting Gold

Since the proportion of gold in the gold mine is between 17.5 and 18, the difference between the proportion of gold and the gangue is very large, so the method of gravity beneficiation can be used for beneficiation. Gravity beneficiation equipment includes mineral jigs, sluice boxes, centrifuges, shakers, etc.

Because the jigging machine has the advantages of large processing capacity, small equipment investment, small floor space, simple structure, and convenient maintenance, most concentrators use jigging machines to extract gold. But only when you know how to use the jig machine correctly can you let it produce more gold for you.

Next, let me share with you the three factors that affect the beneficiation of the jig machine and how to use them to improve the efficiency of the jig machine for extracting gold.

3. Principles of Operating Equipment

Jigging machine is a gravity beneficiation equipment with a long history, and it occupies a very important position in a variety of beneficiation industries. With the continuous exploitation of mineral resources and the continuous improvement of social productivity, the efficiency of jigging beneficiation must be greatly increased to ensure the smooth development of the beneficiation industry. The main factors that affect the beneficiation of the jig are three elements: the characteristics of the material, the structure of the jig, and the operation of the equipment.

3.1 Stroke Length and Stroke Frequency.

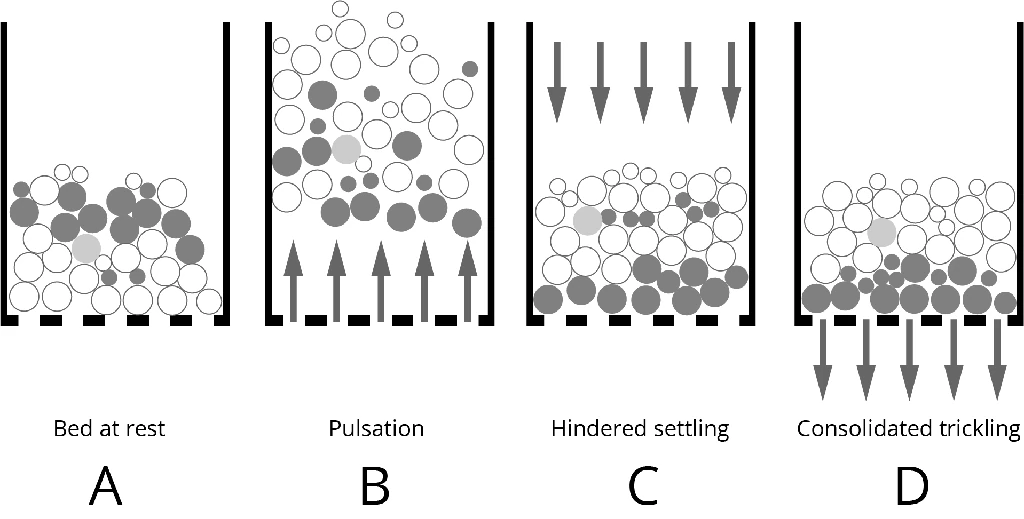

The stroke length and frequency of the mineral jig will affect different water flow characteristics and bed loose time and space conditions. If the water velocity is too large, the velocity thrust will be increased. If the water velocity is too small, the bed looseness will be too small, which will affect the looseness and transportation of the bed.

3.2 Add Water Under the Sieve.

Adding water under the screen can not only supplement the amount of water consumed by the tailings but also adjust the suction effect of the bed and control the quantity and quality of the concentrate. By controlling the addition of water under the screen, the density, processing capacity, and thickness of the material can be adjusted to suit the beneficiation, increase the beneficiation efficiency, and improve the beneficiation quality.

3.3 The Nature and Composition of the Mineral Bed.

The nature and composition of the bed layer of jigging beneficiation, the speed of ore grain layering, the difference of gangue density, etc. can all affect the efficiency of beneficiation. We usually determine the thickness of the bed according to the height of the tail of the jig, and the bed is generally between 100 and 200 mm.

The above are several factors that affect the efficiency of the jigging machine. What we must pay attention to is that they are not isolated from each other. In the production of the jig machine, we must pay attention to the changes of each data, and adjust the equipment according to the data changes, in order to ensure the high yield and efficiency of the jig machine and the recovery rate of gold.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us