OVERVIEW

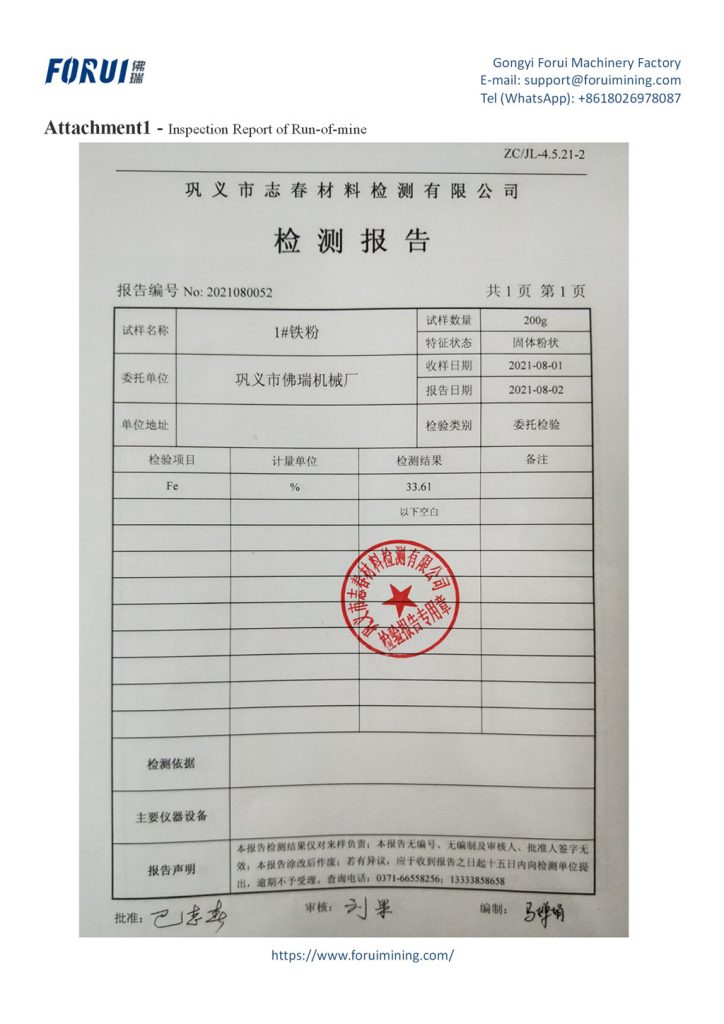

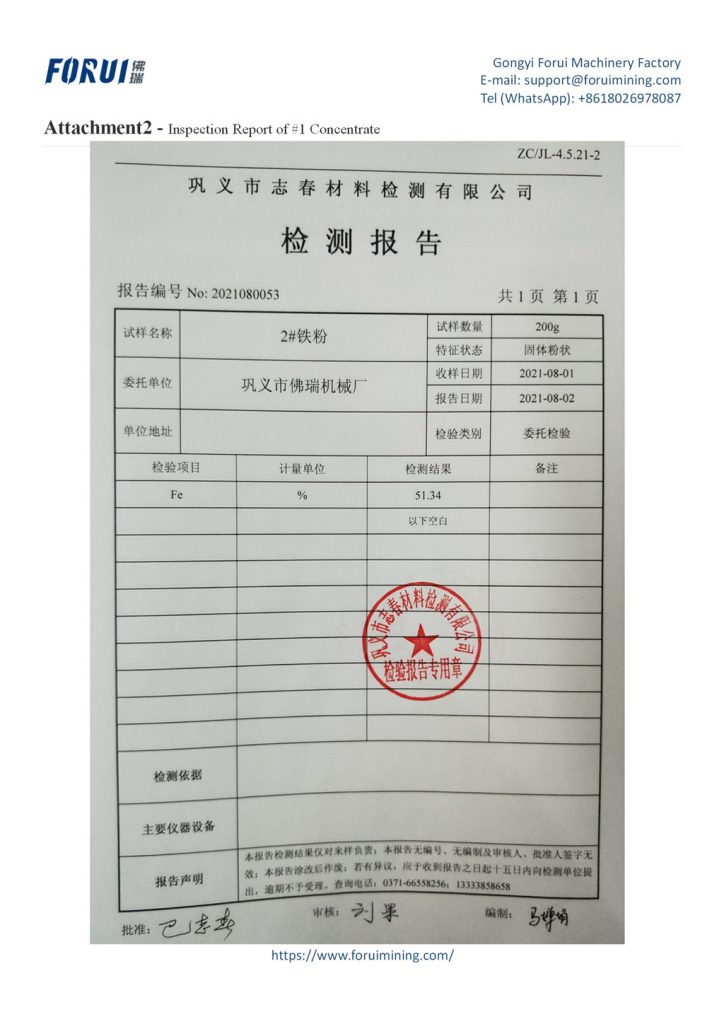

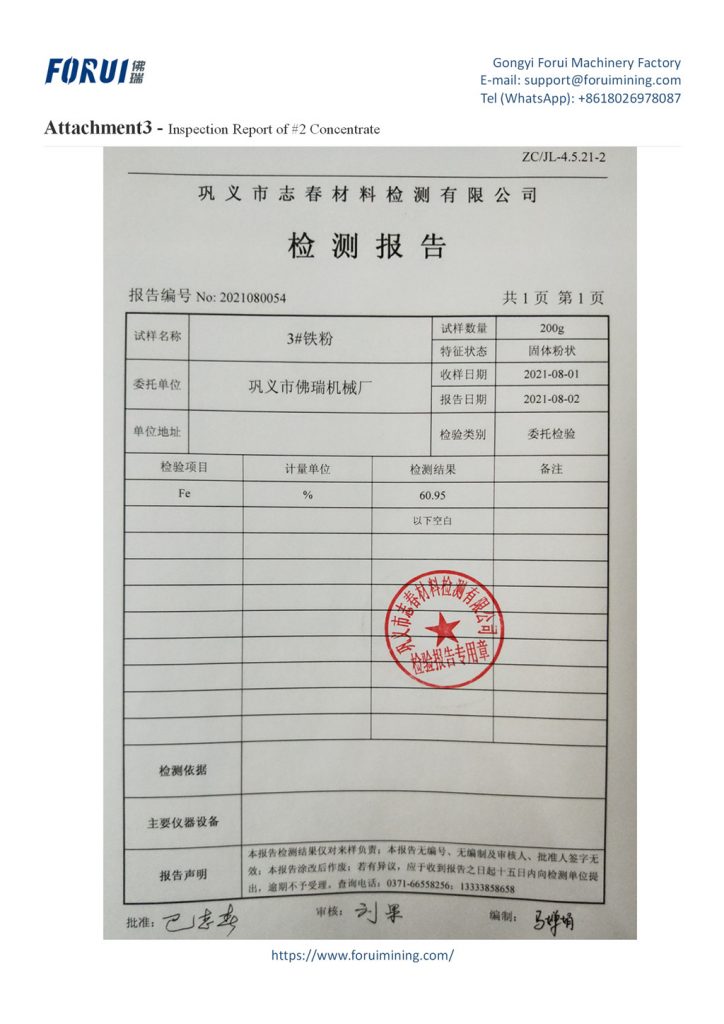

Hello, everyone, this is Asa from Forui Machinery. The day before yesterday we received magnetite from our customer in South America. The magnetite grade is about 28-30%, and our customer asks us to improve its grade to more than 62%. Now we will do the beneficiation experiment. Let’s take a look. The beneficiation process is as follows:

1. Crushing

We will crush them first. In order to enter the ball mill for grinding.

2. Grinding

The main function of grinding is to separate the magnetite from the gangue. We load the crushed magnetite into a small ball mill. Then, we load the grinding medium steel balls into the ball mill.

3. Screening

We screen the magnetite processed by the ball mill.

4. Magnetic Separation

Finally, we conduct a magnetic separation experiment on them.

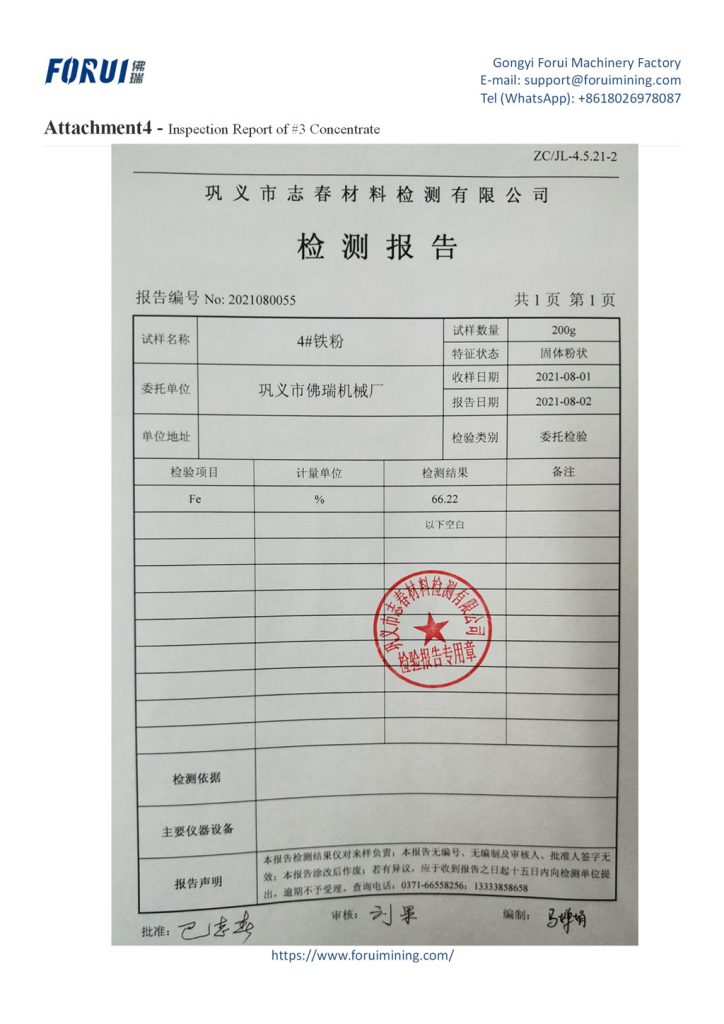

We have improved the grade to above 66%, if you want to know the result of magnetic separation, please leave a message in the comment area, and remember to follow me.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in the lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us