Introduction of Gravity Gold Concentration Program

First of all, I wish you all a happy New Year’s Day 2021 and a blessed New Year! In the previous article, we shared “Very Simple and Efficient Placer Gold Beneficiation Program“. Today we are going to share another similar high-yield gravity gold concentration program. We can see from the plan that compared with the plan of the previous sluice box, today this plan uses a mineral jig as the beneficiation equipment. Let me share the details of this plan.

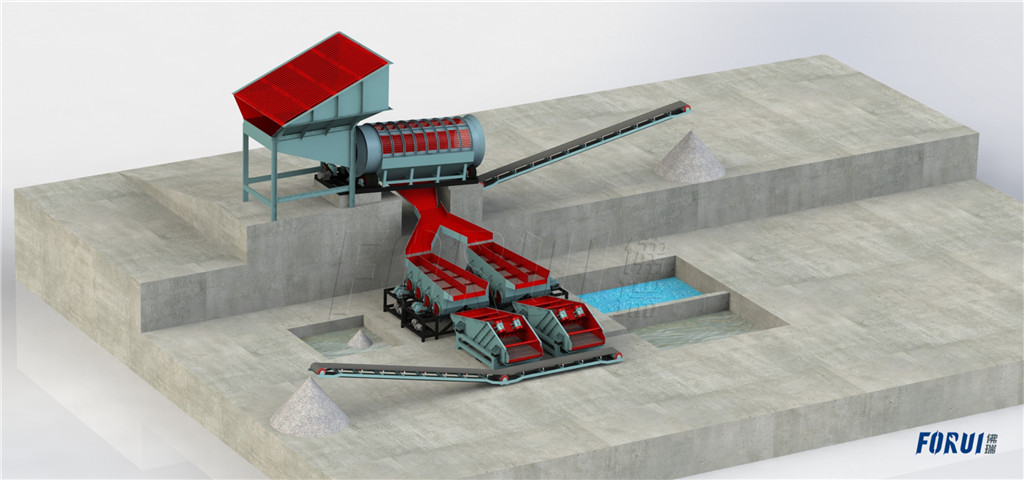

Major Equipments

Sliding screen, hopper, belt conveyor, trommel screen, mineral jig, dewatering screen, sedimentation tank, etc.

Preparation Operation of Gravity Gold Concentration

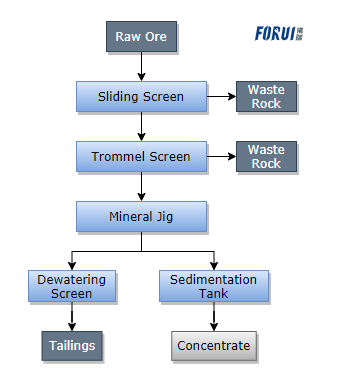

First, a sliding screen is used to screen the raw ore for the first time, and the large pieces of waste rock are screened and removed. Then the sieved placer gold ore is fed into the hopper. After the raw ore is fed into the hopper, the hopper sends the raw ore to the trommel screen. The trommel screen has two main functions: washing and sieving placer gold ore.

Under the action of high-pressure water washing, the mud mass in the placer gold mine is broken and decomposed. On the one hand, it can separate the useful minerals (gold) in the placer gold mine from the waste rock, and on the other hand, it can prevent the screen of the trommel from clogging.

After sieving by the trommel, it is divided into two particle grades. At the end of the trommel, the oversize is discharged. The oversize is large pieces of waste rock. The belt conveyor will transport these waste rocks to the waste rock pile for disposal.

What is discharged under the trommel is the undersieve, which contains almost all useful minerals (gold).

Gravity Gold Concentration

After the previous preparations, the trommel will feed the placer gold ore that meets the feed size of the mineral jig into the mineral jig. Formally entered the beneficiation stage. The mineral jig is a kind of commonly used gravity beneficiation equipment, which mainly uses the principle of gravity beneficiation to beneficiate.

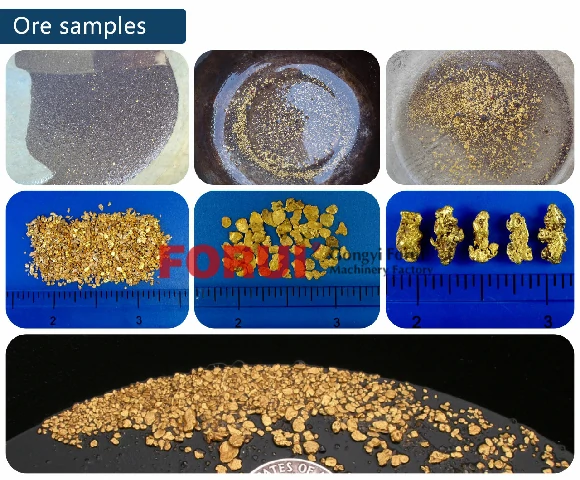

Gravity concentration is a method to separate minerals according to different mineral density and different settling velocity in the medium. So does Gravity Gold Concentration.

According to the second law of thermodynamics, any closed system tends to decrease in free energy. That is, if a process is accompanied by a decrease in energy before and after the change, the process will proceed spontaneously. The stratification process of the bed in the mineral jig machine is a process of potential energy reduction. Therefore, when the bed is properly loosened, it is an inevitable trend for the heavy mineral particles to fall and the light mineral particles to rise.

Because the specific gravity of gold in placer gold is relatively large, the average is between 17.5-18. This value is much larger than the sand in the placer gold ore. In the mineral jig machine, the water flow is constantly moving up and down. Placer gold mines are stratified according to the difference in specific gravity in this kind of water flow. The dense gold particles descend and are finally discharged from the lower concentrate port. The low-density sand and gravel are in the upper layer and are finally discharged from the tailings mouth with the flow of water.

As mentioned above, the process of ore dressing a placer gold deposit using a mineral jig is continuously carried out under the action of water flow.

Result & Features

The Gravity Gold Concentration has a lot of features below:

- Feeding size range is wide.

- Simple structure, convenient adjustment and easy maintenance.

- Cover a small area, large processing capacity per unit area.

- The whole process only uses water and no pollution. This is the future development trend of the mineral processing industry.

Thank you for reading. Next time, we will share the “High-yield, High Enrichment Ratio Placer Gold Processing Scheme“.

What are your thoughts on the beneficiation plan of placer gold mine? Welcome to leave a message.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!