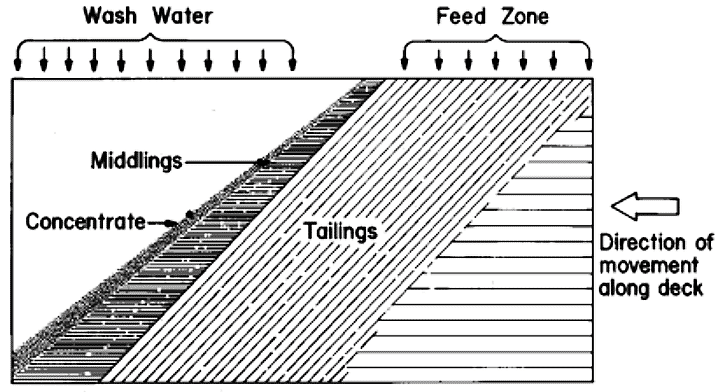

There are many factors that affect the beneficiation effect of the shaking table, among which the main ones are: the structure and operation of the shaking table and the properties of the ore.

Ore Properties

The density, size, and shape of the ore particles in the shaker have a great influence on the mineral processing index. When the relative density difference between heavy minerals and light minerals is greater than 1.5, it can be smoothly beneficiated on a shaking table. Spherical ore particles and coarse particles are easily washed away by water, so under favorable conditions for the difference between spherical and particle size, ore particles with a smaller density difference can be extracted. The ores processed by the shaking table are generally classified according to a constant reduction ratio, that is, hydraulic classification.

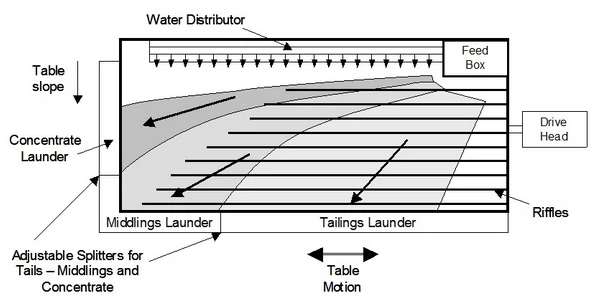

Horizontal Slope and Water Consumption

Both of them mainly affect the lateral movement speed of the ore particles and the looseness of the bed. Increasing the slope can increase the speed of the water flow. Generally, when processing fine-grained materials, the slope should be smaller, and when dealing with coarse-grained materials, the slope should be larger. The slope can be adjusted in the range of 0°~10°. For the slope of different materials, the following values can be used as a reference:

2.1 Coarse materials less than 2mm: 3.5°~4°.

2.2 Materials less than 0.5mm: 2.5°~3.5°.

2.3 Fine-grained materials less than 0.1mm: 2°~2.5°.

2.4 0.074mm mud: about 2°.

Stroke Length and Stroke Frequency

The loosening, stratification, and transportation of ore particles on the bed surface, stroke, and stroke play an important role. Stroke and stroke rate are two important factors related to each other. When selecting fine-grained materials, it is better to use small strokes and high-stroke times. When selecting coarse-grained materials, the opposite is true.

Concentration and Water Supply

The amount of dry ore fed to the shaker and the concentration of ore determine the volume of ore slurry fed. The feed concentration and feed volume have a great influence on the selection of the shaking table. If the feed concentration is too large, the viscosity of the ore slurry will be higher, and the fluidity will be worse. Many kinds of minerals cannot be stratified and zoned. If the concentration is too thin, in addition to reducing the productivity of the shaker, it will also cause the loss of fine-grained concentrate.

The proper slurry concentration should ensure that the slurry has sufficient fluidity and the layering and zoning effect of the ore particles on the bed surface. The feed concentration of the shaker is generally 15%~30%.

Productivity

The productivity of the shaker depends on factors such as the density, particle size composition, operating conditions, and product quality requirements of the processed materials. During roughing, only coarse concentrate is required. The coarser the particle size, the higher the productivity, and vice versa.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us