The shaking table is one of the most refined and widely applied gravity separation devices, particularly in the beneficiation of gold, tin, tungsten, and tantalum–niobium ores. Although the equipment itself appears simple, the separation process depends on the combined effects of deck geometry, asymmetric motion, and controlled water flow.

As a result, when operators lack a clear understanding of these mechanisms, they often encounter blurred banding, coarse mineral loss, concentrate contamination, or unstable recovery. For this reason, this article provides a systematic explanation of shaking table separation—from structural principles to operational control—helping mineral processing plants achieve stable operation and high-grade concentrate.

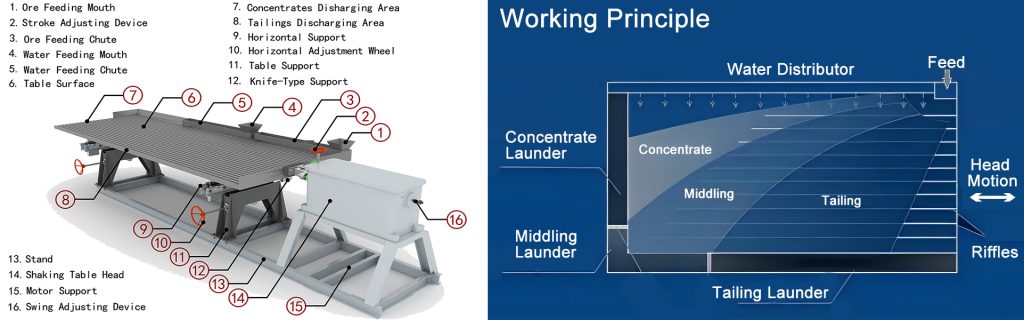

1. Structural Characteristics of the Shaking Table

A shaking table typically consists of a deck, a head-motion driving unit, a supporting frame, and a water distribution system. The deck inclines slightly in both longitudinal and transverse directions and includes riffles that guide particle movement within a thin film of water.

The head motion generates an asymmetric reciprocating stroke in which the table moves forward slowly and returns rapidly. This motion creates acceleration differences, which significantly enhance stratification between particles of different densities and sizes. In addition, transverse wash water flows across the deck to remove light minerals, while denser particles remain within the riffle structure. Together, deck inclination, riffle geometry, water distribution, and asymmetric motion form the operational foundation of the shaking table and enable precise gravity separation under thin-layer conditions.

2. Mechanisms of Mineral Separation

Several forces act on particles simultaneously during shaking table separation. When slurry enters the deck, the riffle geometry first influences particle movement and initiates stratification. As the slurry moves forward, particles enter the thin-film flow region and experience differential inertia generated by the asymmetric deck motion.

Dense and coarse particles develop stronger forward momentum and therefore migrate toward the concentrate end. In contrast, lighter and finer particles move laterally under the action of transverse wash water. The water flow continuously removes light minerals from the upper layer, while heavy minerals settle and migrate steadily along the riffles. As a result, the shaking table forms characteristic banded zones ranging from heavy and coarse particles to fine and light particles.

3. Technical Advantages and Application of the 6S Shaking Table

The 6S shaking table represents one of the most widely used and optimized designs in modern mineral processing. Its improved deck surface, carefully engineered riffle patterns, and adjustable slopes create a stable thin-film flow environment that enhances selective stratification.

At the same time, the eccentric-driven head motion reinforces differential acceleration while maintaining smooth operation and relatively low energy consumption. Moreover, the 6S shaking table offers a broad particle-size application range:

- Coarse sand: 0.5–3 mm

- Fine sand: 0.074–0.5 mm

- Slime particles: down to 0.037 mm

Therefore, operators can apply the same equipment to both roughing and cleaning stages. By precisely adjusting stroke length, frequency, water flow, and deck slope, the 6S shaking table consistently delivers clear banding and high-grade concentrate.

4. Key Factors Influencing Separation Performance

Stroke and Frequency

Stroke and frequency define the acceleration applied to particles and directly influence bed looseness. When acceleration exceeds frictional resistance between particles and the deck surface, particles begin to slide. This sliding behavior plays a critical role in effective stratification.

Water Flow and Deck Slope

In addition, water flow and deck slope determine lateral mineral transport. Excessive water flow may wash fine heavy particles into tailings, whereas insufficient water flow limits light mineral removal and reduces concentrate grade.

Feed Characteristics

Feed characteristics also influence separation results. Therefore, maintaining a consistent feed concentration—typically between 15% and 30%—ensures predictable particle behavior.

5. Operational Control and On-Site Optimization

Optimal shaking table performance requires continuous observation and parameter adjustment rather than fixed settings. A well-operating table shows a loose and uniform bed, clear band formation, and stable settling of heavy minerals. In practice, operators evaluate performance by observing bed behavior, water film quality, and mineral movement. By adjusting stroke, frequency, water flow, deck slope, and feed rate accordingly, plants maintain stable operation even under changing ore conditions.

Conclusion

The shaking table is a technically refined and highly effective device for fine gravity separation. Its performance depends on the interaction between particle dynamics, deck motion, and water flow. When operators coordinate these parameters properly, the shaking table consistently produces high-grade concentrates with low losses, clear banding, and excellent operational stability. For processing plants seeking improved recovery and consistent metallurgical results, mastering shaking table principles and operational control remains essential.