Introduction

The vertical mill also known as Raymond Mill, referred to as high pressure grinder, high pressure mill, high pressure roller mill, high pressure roller grinder.

Reymond Mill of our company is a strengthened type, combining the successful experience at home and abroad and popular Raymond Mill technology optimization upgrade. The biggest improvement is the addition of a high-pressure spring system for the roller section. With a wider range of grinding materials, grinding particles finer, grinding efficiency higher outstanding advantages, is a highly efficient energy-saving mill equipment.

The roller mill is widely used in mining, construction, building materials, Water Conservancy, hydropower, metallurgy, chemical and other industries in the material processing field, such as calcium carbonate grinding, gypsum powder processing, power plant desulphurization, non-metallic mineral powder, coal powder preparation and other industrial grinding projects.

Structure

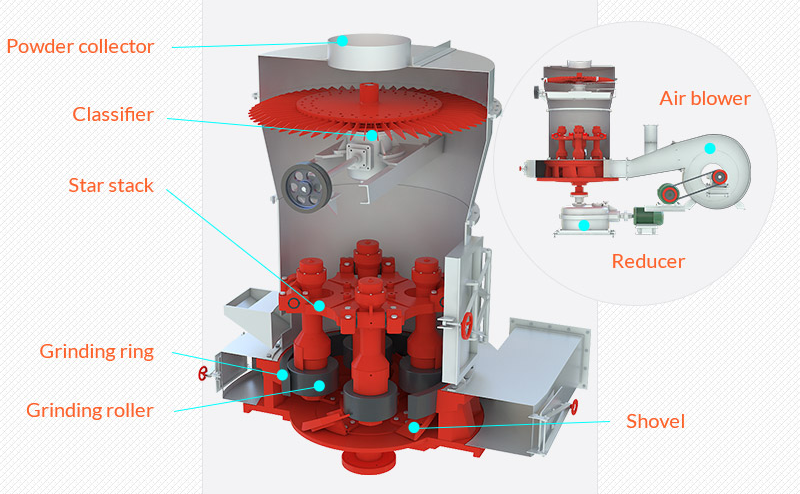

A Raymond mill is mainly composed of grinding roller, grinding ring, star stack, shovel, air blower, classifier, reducer, and air collector.

Inside the mill, the main shaft rotates to generate centrifugal force, causing the grinding roller to swing outward and press against the grinding ring. The rotating shovels scoop up raw materials and project them between the rollers and the ring where the grinding takes place.

Features of Vertical Mill

Force produced from milling roller connected by pull rod and high pressure spring can avoid damages caused by bulk materials to the equipment.

Resilient coupling between main engine and the separator can reduce vibration and noise and improve service life of the equipment.

Because of connecting crushing, drying, grinding, classifying and transmission together with simple system and compact layout, it covers about 50% of the area of the ball mill system.

It can be outdoor arrangement, which can reduce the investment cost a lot.

Forui Machinery, founded in 1986. We are one of the leading suppliers of beneficiation pieces of equipment in Asia. Don’t hesitate to Contact Us, if you have any questions about beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory is dedicated to serving you!