Introduction

The mainstream beneficiation method for lead-zinc ore is flotation, but in recent years, restricted by environmental protection requirements, the application of flotation has become less and less, and it has been replaced by gravity beneficiation. Gravity beneficiation has many advantages compared with flotation. For example, gravity beneficiation has low investment, low cost, and no pollution.

But as a new method of lead-zinc ore beneficiation, many people in the industry still have doubts about it, so today we will share the gravity beneficiation process of lead-zinc ore.

Lead-zinc Ore Beneficiation Process

The gravity beneficiation process of lead-zinc ore is actually not complicated and is similar to the general gravity beneficiation process. Gravity beneficiation processes basically go through processes such as crushing, screening, gravity beneficiation, and dehydration.

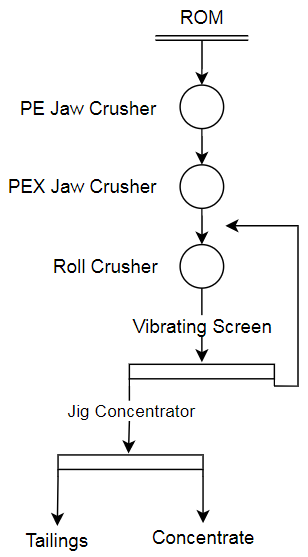

We must first observe whether the raw ore of lead-zinc ore meets the basic requirements of gravity beneficiation. If it meets the requirements, then determine the crushing particle size according to the size of the ore’s embedded cloth. According to these crushing particle sizes, the crushing process and the gravity beneficiation process are selected. For example, coarse-grained lead-zinc ore can be processed through coarse crushing, fine crushing, screening, and jigging. The gravity beneficiation process flow chart is as follows:

The lead-zinc ore is coarsely crushed by the jaw crusher and then enters the counter-roller crusher for fine crushing. The material produced by the roller crusher has the lowest rate of excessive crushing, so we recommend that you use a roller crusher. Because lead-zinc ore is fragile, it is easy to cause over-crushing during the crushing process, and the over-crushing lead-zinc ore is difficult to effectively recover in the gravity beneficiation process, so we recommend the use of this roller crusher with the lowest over-crushing rate.

The lead-zinc ore crushed by the roller crusher enters the linear vibrating screen for screening, the lead-zinc ore that has not reached the monomer dissociation is screened out, and the lead-zinc ore is returned to the crusher to continue crushing. The lead-zinc ore that meets the particle size requirements is sent to the silo, and a vibrating feeder is installed under the silo to evenly feed the lead-zinc ore into the jig, and then gravity beneficiation is carried out in the jig. The concentrate obtained from the jig machine enters the concentrate pool, and the tailings are dehydrated by a dewatering screen and then drained. This completes the entire process of gravity beneficiation of lead-zinc ore.

The entire beneficiation process uses circulating water, does not use any chemicals, and does not pollute the environment. The beneficiation equipment used in the gravity beneficiation of lead-zinc ore includes jaw crushers, roller crushers, linear vibrating screen, jig machine, dewatering screen, and other equipment. The specific equipment configuration needs to be determined according to customer requirements and actual conditions.

Gongyi Forui Machinery Factory is a high-quality enterprise specializing in the production of beneficiation equipment. Over the years, it has produced gravity beneficiation, magnetic separation, flotation, and other beneficiation equipment, and has accumulated a lot of practical experience. Forui Machinery is involved in lead-zinc ore, gold ore, fluorite, barite, pyrite, hematite, limonite, magnetite, manganese ore, antimony ore, tungsten ore, tin ore, celestite, etc. In the field of beneficiation of a variety of minerals, fruitful results have been achieved.

If you need equipment quotation and process flow, please feel free to Contact Us