When processing high-density minerals such as tin, tungsten, and tantalum–niobium ores, mineral processing plants often prioritize stable recovery, clear separation, and controllable operating costs over maximum throughput.

As ore grades decline and valuable minerals become increasingly fine-grained, plants must recover fine heavy particles more reliably than ever before. For this reason, the shaking table continues to play an essential role in fine gravity separation and remains a core piece of equipment in many beneficiation circuits worldwide.

How a Shaking Table Achieves High-Precision Separation

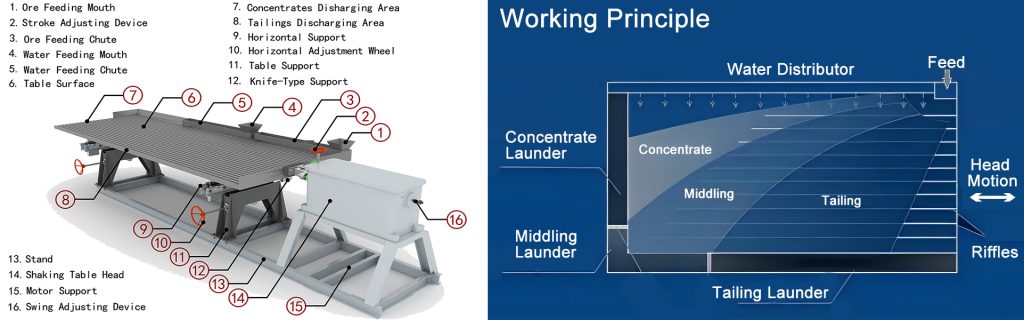

Unlike coarse gravity equipment that mainly relies on density differences, a shaking table operates under a thin-film water flow environment. The equipment achieves separation through the combined action of deck structure, asymmetric reciprocating motion, and transverse wash water.

As a result, minerals stratify and migrate in a highly controlled manner. Rather than simply separating heavy from light minerals, the shaking table produces clear and stable banding. This behavior makes the equipment especially suitable for applications where concentrate grade and recovery stability matter most.

Why Processing Plants Still Choose Shaking Tables

High Separation Accuracy

For fine particles with a clear density contrast, shaking tables consistently form well-defined separation bands. Heavy minerals concentrate along the riffle zones, while lighter gangue gradually moves away under the action of wash water. As a result, plants significantly reduce losses of fine valuable minerals.

Stable and Highly Controllable Operation

In addition, shaking tables offer excellent operational flexibility. Operators can adjust stroke length, stroke frequency, water flow rate, and deck slope to respond effectively to changing ore characteristics. Therefore, plants maintain stable performance without frequent equipment replacement or major process modifications.

Low Capital and Operating Costs

Moreover, shaking tables feature a mature structure, few wear parts, and simple maintenance procedures. These advantages allow plants to operate the equipment at relatively low long-term cost. For small and medium-sized mines, shaking tables provide a practical balance between investment and metallurgical performance.

The 6S Shaking Table: A Proven Engineering Choice

Among various shaking table designs, the 6S shaking table stands out as one of the most widely used and technically mature models. Its optimized deck surface and riffle configuration help establish a stable and uniform water film, which is essential for fine-particle stratification.

At the same time, the eccentric-driven head motion delivers sufficient differential acceleration while maintaining smooth operation. As a result, the 6S shaking table performs well in continuous production environments that demand consistent separation quality.

Typical Applications of the 6S Shaking Table

- Cleaning of tin, tungsten, and tantalum–niobium concentrates to improve final grade

- Upgrading intermediate products from spiral concentrators or jig machines

- Tailings reprocessing to recover fine or partially liberated heavy minerals

When plants control feed particle size properly and avoid excessive clay content, the 6S shaking table achieves high-grade concentrates with low losses. Therefore, many operations adopt it as a key fine separation stage rather than a high-throughput device.

Engineering Perspective

From an engineering perspective, processing plants should not regard shaking tables as outdated equipment. On the contrary, shaking tables remain well-proven precision gravity separators. They deliver reliable performance in fine-particle applications where accuracy and operational control are essential.

About Forui

With extensive experience in gravity separation equipment and mineral processing flowsheet design, Forui Machinery supplies shaking tables and complete gravity beneficiation solutions for tin, tungsten, tantalum–niobium, fluorite, and other heavy mineral ores. The focus remains on delivering reliable equipment and practical solutions that support stable, long-term plant operation.