Introduction

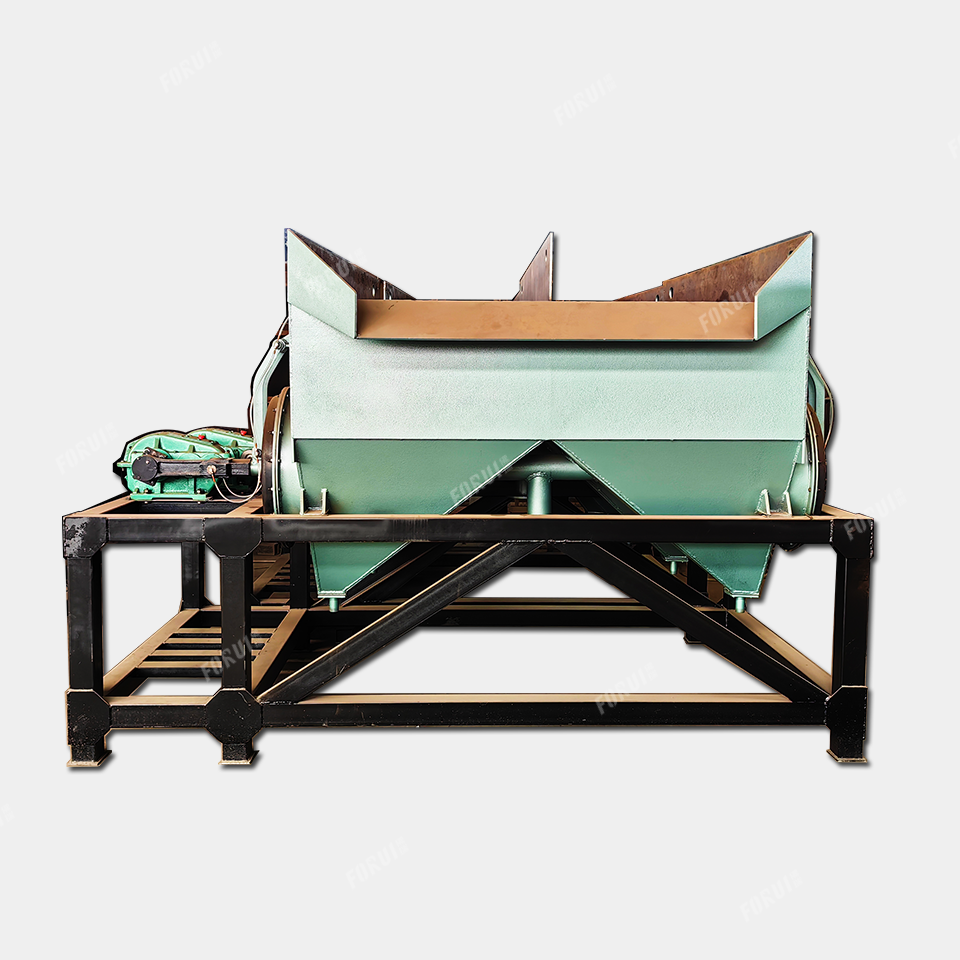

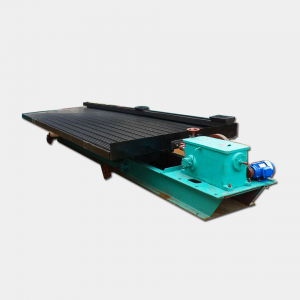

2LTC6109/8T jig concentrator is commonly known as trapezoidal jig machine. It is developed by our country. Initially it was used for the pre-beneficiation of hematite, but later it was discovered in the process of beneficiation that it has advantages that other types of jigs do not have. For example, it has four independent beneficiation tanks, and the stroke length and stroke frequency of each beneficiation tank can be adjusted independently.

Therefore, one such device has the capacity of four machines. It has an ideal beneficiation effect for unclassified minerals within a certain particle size range. Therefore, the trapezoidal jig is widely used in the field of recovery of various ore and smelting slag. Its powerful functions have created a lot of value for customers.

Features

1. Large feed size and wide feed size level.

2. The equipment occupies a small area and the processing capacity per unit area is large.

3. The inlet is narrow and the outlet is wide. The material goes through four different beneficiation processes from entering the jig concentrator to exiting the jig concentrator. At the same time, the material layer is getting thinner and thinner, and the recovery rate has been greatly improved.

4. Simple structure, convenient adjustment and easy maintenance.

5. It has four independent beneficiation troughs, each trough’s stroke length and stroke frequency can be adjusted independently. One trapezoidal jig has the capacity of four machines.

Working Principle

After the raw ore is crushed, it reaches the range of the feed size of the mineral jig concentrator. Then the ore is evenly fed into the feeding trough of the jig machine through the feeding device. During normal operation, the rocker arm swings back and forth under the drive of the motor. The distance of the swing rod moving up and down can be adjusted by adjusting the eccentricity of the eccentric shaft, and the stroke rate of the jig machine can be adjusted by adjusting the motor speed.

The rocker arm swings back and forth regularly to drive the diaphragm to move back and forth, which in turn produces regular up and down fluctuations in the water flow in the jig concentrator. Since the pulsating curve produced by the eccentric link mechanism is a sine wave curve, the water flow produced by this type of jig concentrator is also similar to the sine wave pulsating water flow.

The sine wave pulsating curve forms a vertical alternating current force in the jig machine, and the minerals entering the tank of the jig machine can be re-layered under the action of the vertical alternating medium flow. The denser mineral particles settle fast in the water flow and are located in the lower space of the material layer. However, mineral particles with low density have a slow settling speed in the water flow and are located in the upper space of the material layer.

Due to the difference in density, it is difficult for materials with low density to enter the lower space through the layer of materials with high density. Therefore, the material entering the mineral jig machine is roughly divided into two material layers. The heavy minerals enter the concentrate tank through the screen, and the light minerals enter the tailings tank for discharge. The materials are continuously fed into the jig concentrator and discharged separately after mineral processing, forming a continuous jig beneficiation process.

Mineral Processing Experiment for Manganese Ore

Client Case for Manganese Ore

Online Consultant

Gongyi Forui machinery factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation.