Product

Gem stones such as ruby, sapphire, diamond, etc. are very suitable for gravity separation and screening. Sapphire and ruby ore is a red corundum gemstone, primarily composed of aluminum oxide. As a mineral crystal, sapphire occurs at low concentrations in its ore and requires mineral processing equipment to be separated from gangue and river sand.

The diamond / sapphire / ruby washing plant usually adopts mineral jigs as the main equipment.

Raw Ore

Gem in Mineral Jig

GEM after washing

Gem after picking

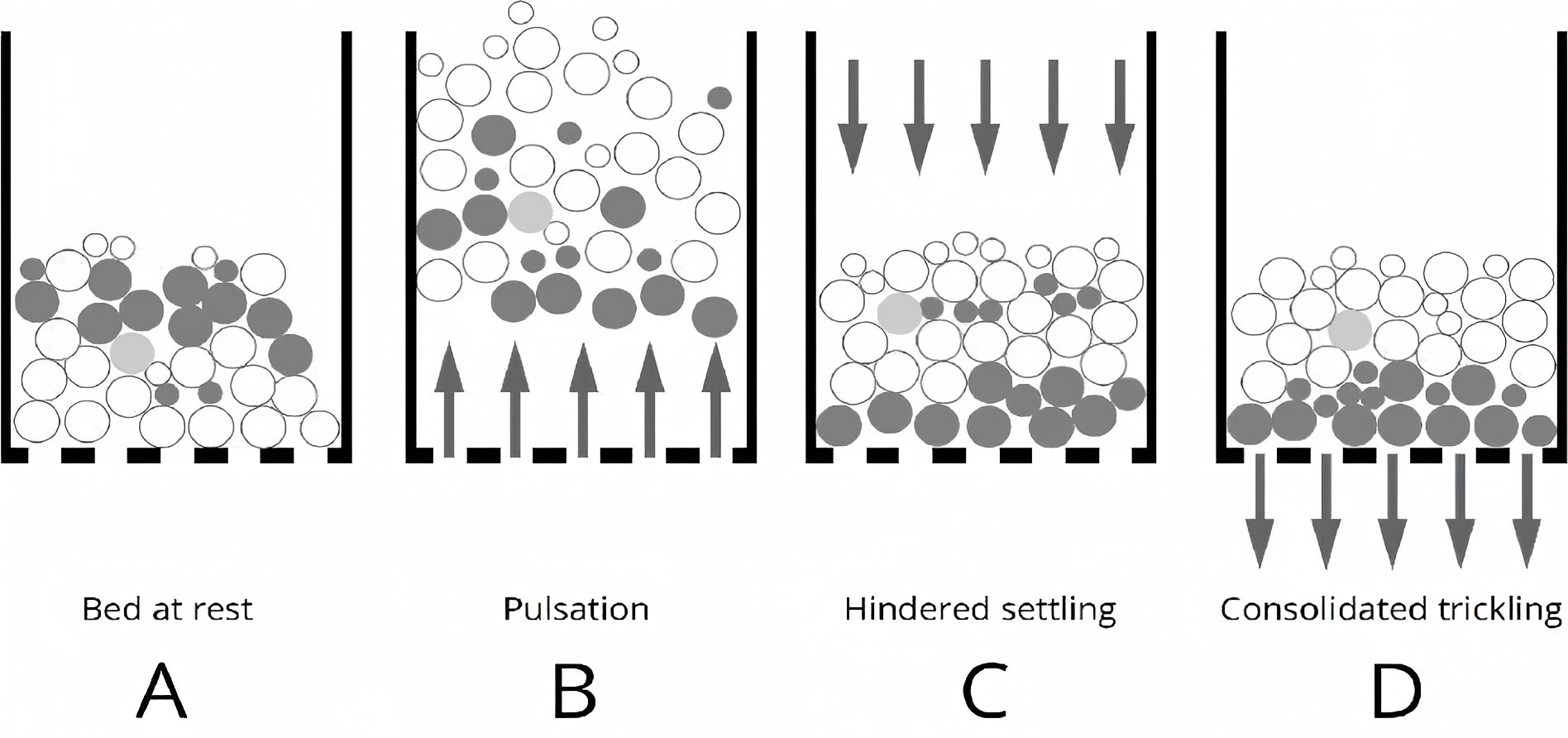

Working Principle

Sapphires, ruby, diamond have a specific gravity of 4.0-4.1, significantly different from gangue minerals. Additionally, they exhibit a high degree of individual liberation, making them highly suitable for gravity separation. By utilizingmineral jig, sluices, and other gravity separation equipment, sapphires can be effectively recovered from placer deposits.

This method offers a wide size range (0-50mm), high processing capacity, stable separation results, and high recovery rates.

Processing Flow

01. Washing and Screening

Depending on the characteristics of the gem stone raw ore, trommel screen or trommel scrubber are used for washing and screening the gem ore.

This process separates gem stone particles larger than 3mm from finer particles smaller than 3mm, which are then sent to jigs and sluices respectively.

02. Gravity Separation

Coarse gem stone particles (3-50mm) are separated using a mineral jig, where qualified sapphire crystals are screened.

Fine gem particles below 3mm are sent to small jig or sluices for further enrichment and separation of gem tones.

03. Dewatering

After gravity separation, dewatering screens are used to dehydrate the processed sapphire, preparing them for further treatment.

Product Features

The main features of FFR Diamond / Sapphire / Ruby Washing machine are as follows:

01. Low Investment, Low Cost:

This solution employs energy-efficient gravity gem stone technology, making it suitable for small to medium-sized gem stone washing plants.

02. Environmentally Friendly:

The process utilizes circulating water, avoids chemical agents, and produces no secondary pollution, ensuring no adverse environmental impact.

03. High Recovery Efficiency:

This solution achieves a best recovery rate is 95%, delivering significant profits to enterpris.

Customized Solutions

Customized Gem Stone Washing Solutions

As a professional manufacturer of sapphire processing equipment, FRP has extensive experience in handling various ore, including sapphire, sapphire, diamond, etc. We can provide customized solutions based on your specific needs, including:

*Process Design:

Designing a suitable mineral processing flow based on the characteristics of your sapphire ore.

*Equipment Configuration:

Providing appropriate crushing equipment, magnetic separation equipment, gravity separation equipment and more.

*Sample Testing:

Conducting sapphire sample processing tests to verify the effectiveness of the process.

Online Consultant

To find out more about our products and solutions, please fill out the form below and we will get back to you shortly.