Introduction

The production line is for processing fluorite ore dressing, whose function is to improve the grade of fluorite ore. So as to meet the needs of industrial production. The main component of fluorite is calcium fluoride, which plays a very important role in metallurgical industry and chemical industry.

But in general, the grade of fluorite ore is difficult to meet the requirements of industrial production.

Therefore, it is necessary to design a processing line to treat fluorite ore. So what is the process flow and equipment configuration of the fluorite concentrator? We here to introduce the fluorite beneficiation production line process and equipment configuration, for reference.

Fluorite Ore Dressing Process

Fluorite processing lines often consist of two or three processes. Such as:

- For fluorite ores with coarse Mosaic size, the ore dressing process generally includes three processes of hand dressing, gravity dressing and flotation.

- For fluorite ores with uneven Mosaic size, the ore dressing process generally includes two processes: gravity dressing and flotation.

- For low-grade fluorite ores with poor quality, and mutual impregnation of fluorite and waste rock, they can only be extracted by flotation.

Therefore, different ore properties, fluorite processing line process is also different. This paper introduces the most comprehensive technological process for the reference of the industry: hand separation – gravity beneficiation – floating joint process.

Fluorite Ore Dressing Process – Hand Ore Dressing

Hand separation of fluorite ore is the process of selecting large fluorite crystals from the ore for use in the metallurgical industry. This method, though unwieldy, still plays an irreplaceable role in the processing of large fluorite ores.

In particular, coarse fluorite ore larger than 50mm can reach the feeding particle size range of gravity dressing equipment through crushing, but it will break the crystal structure, resulting in the generation of powdery ore, unable to retain large fluorite that can be used as art sculpture.

Fluorite Ore Dressing Process – Gravity Concentration

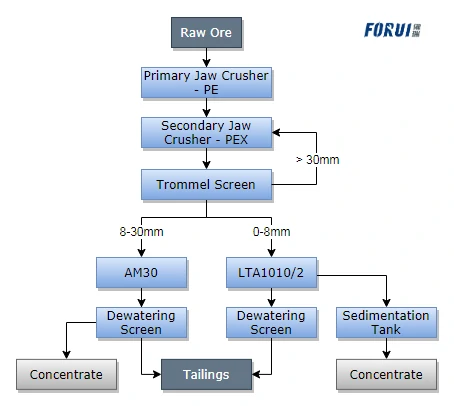

The gravity dressing of fluorite ore is a method of dressing by the gravity dressing equipment of mineral jig. It is a kind of mineral processing method for the mechanized extraction of medium and fine fluorite ore.

This method has the features of high efficiency, energy saving and environmental protection. Gravity dressing can produce most of the fluorite products used in the metallurgical industry. It is the core method of producing metallurgical grade fluorite ore.

Fluorite Ore Dressing Process – Flotation

Fluorite flotation is a method of purifying fluorite impregnated with fine particles by means of flotation. This method is mainly used to produce high quality chemical grade fluorite powder.

It is also the only way to produce chemical grade fluorite powder. Flotation is not friendly to small and medium sized fluorite concentrators because of its high index and large equipment investment and operation cost.

Summary

The production line of fluorite dressing usually contains the above three processes, which respectively complete the recovery and utilization of coarse, medium and fine grade fluorite ore.Pre-selection by hand picks out large blocks of fluorite for carving ornaments and artwork.

Medium and coarse grade fluorite blocks and particle ores produced by gravity dressing are used as flux in metallurgical industry.The fine grade fluorite powder produced by flotation is used to produce hydrofluoric acid in chemical industry.

This all-directional fluorite dressing line is suitable for coarse, fine and evenly embedded fluorite ore. It can produce fluorite ore for many uses and is suitable for large fluorite concentrator.

The process flow and equipment configuration of fluorite concentrator need to be designed according to the actual situation. Gongyi Frei machinery Factory is a professional manufacturer of fluorite dressing equipment. Our factory has rich experience in fluorite dressing production line, fluorite dressing plant equipment configuration and technological process. We can conduct small-scale fluorite dressing test, design dressing process and configure dressing equipment for customers free of charge. Do not hesitate to contact us.

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipments in Asia. Don’t hesitate to Contact Us, if you have any question of beneficiation. And welcome to visit our company. Gongyi Forui Machinery Factory dedicated to serve you!