Introduction

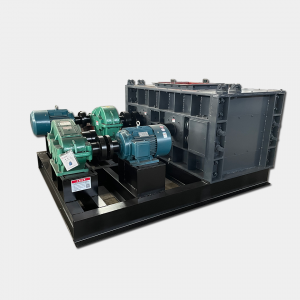

A Hammer crusher is a kind of impact crusher, which mainly relies on hammerhead impact material to achieve the purpose of crushing. Hammer crushers mainly include single-stage hammer crusher, single-stage fine crusher, high-efficiency fine crusher, ring hammer crusher, counterattack crusher, and reversible crusher.

Main Purpose

The hammer crusher is used to crush various medium-hard and weakly abrasive materials. The compressive strength of the material does not exceed 100MPa, and the moisture content is less than 15%. The crushed materials are coal, salt, chalk, gypsum, bricks, limestone, shale, etc. It is also used to crush wood, paper, or crushed asbestos cement with a strong fiber structure, elasticity, and toughness to recycle asbestos fibers. In addition, the hammer crusher can not only be used in crushing production lines, sand production lines, but also in the beneficiation production line instead of cone crushers.

The main working part of the hammer crusher is a rotor with a hammer (also known as a hammerhead). The rotor consists of the main shaft, a disc, a pin, and a hammer. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing, and grinding action of the high-speed moving hammer. In the lower part of the rotor, there is a sieve plate, and the particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, and the coarse particles larger than the sieve hole size remain on the sieve plate and continue to be hit and ground by the hammer, and finally pass through the sieve plate Exhaust from the machine.

Working Principle

The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feeding port, and is crushed by the impact, impact, shearing, and grinding action of the high-speed moving hammer. In the lower part of the rotor, there is a sieve plate, and the particles smaller than the sieve hole size in the crushed material are discharged through the sieve plate, and the coarse particles larger than the sieve hole size are retained on the sieve plate and continue to be hit and ground by the hammer, and finally pass through the sieve plate Exhaust from the machine.

Technical Parameters

| Model | Max Feed Size (mm) | Discharge Size(mm) | Capacity(t/h) | Power(kw) | Weight(t) |

|---|---|---|---|---|---|

| Φ400×300 | 100 | 0-30 | 5-8 | 11 | 0.5) |

| Φ600×400 | 100 | 0-35 | 10-12 | 18.5 | 1.03 |

| Φ600×600 | 100 | 0-35 | 12-18 | 45 | 2.14 |

| Φ800×600 | 120 | 0-45 | 20-25 | 55 | 2.45 |

| Φ800×800 | 120 | 0-45 | 35-45 | 55 | 3.05 |

| Φ1000×800 | 200 | 0-45 | 25-40 | 110 | 6.5 |

| Φ1000×1000 | 200 | 0-45 | 40-80 | 132 | 7.6 |

| Φ1250×800 | 200 | 0-45 | 20-50 | 132 | 11.7 |

| Φ1250×125 | 200 | 0-45 | 90-110 | 185 | 13.2 |

| Φ1400×140 | 250 | 0-45 | 120-170 | 280 | 17.2 |

| Φ1600×160 | 350 | 0-60 | 220-280 | 450 | 22.8 |

Online Consultant

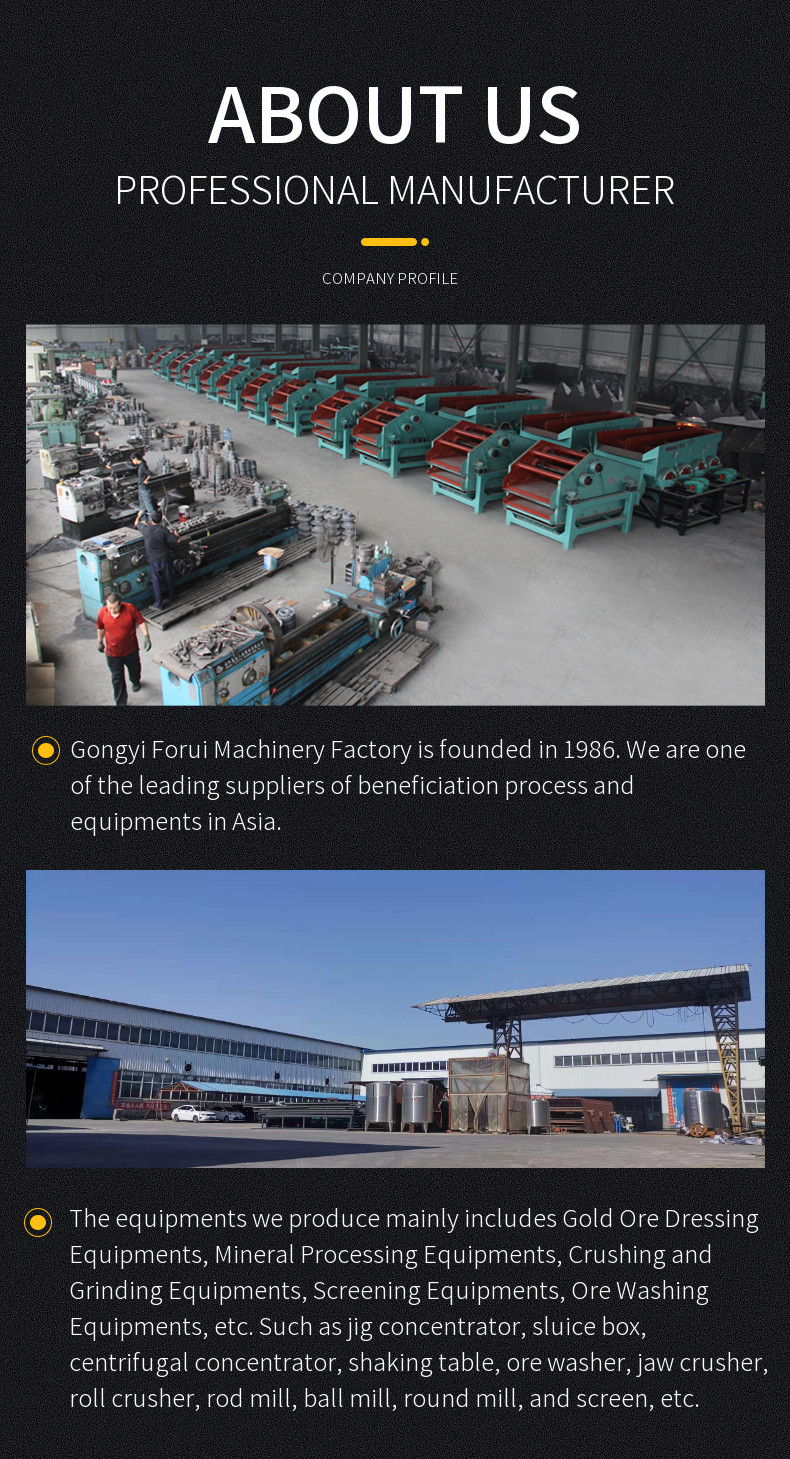

Gongyi Forui Machinery Factory, founded in 1986. We are one of the leading suppliers of beneficiation equipment in Asia. Don’t hesitate to Contact Us, if you have any questions.